Biomedical Engineering Reference

In-Depth Information

H

2

O

CO

2

CH

4

0.1

H

2

0.01

0.001

CO

300

400

500

600

700

800

900

1000

1100

T

, °C

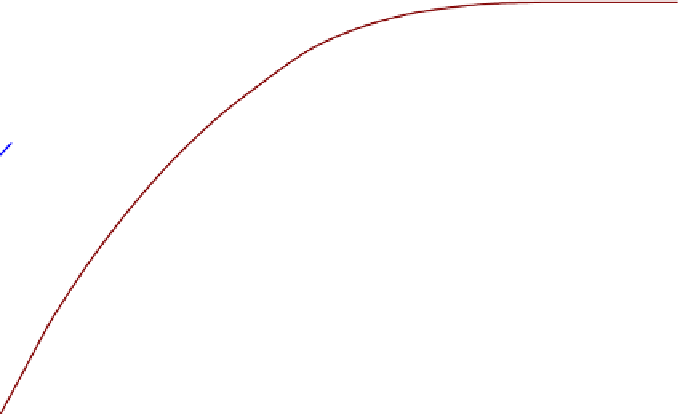

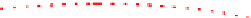

FIGURE 5.5

Equilibrium mole fractions for the carbon-steam reaction as a function of temperature.

Syngas can also be made using naphtha or other hydrocarbon feedstocks, such as the

methane from natural gas,

þ 3

H

2

(5.30)

Note that coal produces CO and H

2

in a 1:1 ratio, naphtha in a 1:2 ratio, and methane in

a 1:3 ratio. Because of the need in thermal energy to shift the reactions forward, oxygen

(or air) is usually supplied to partially oxidize the carbon (and hydrogen) to maintain

energy balance. An excess of H

2

CH

4

þ

H

2

O

/

CO

is thus usually desired; so alkanes are the preferred

feedstock.

Existing syngas plants operate by direct oxidation of natural gas

CH

4

þ

1

=

2

O

2

/

CO

þ 2

H

2

(5.31)

using pure O

2

from a liquid air plant. This process, called autothermal reforming, uses this

exothermic reaction in an adiabatic reactor and produces the 1:2 ratio of CO:H

2

that is ideal

for methanol or FT processes.

Today, more attention is paid to the gasification of renewable biomass. Lignocellulosic

biomass holds the most promising position in a sustainably renewable world. Dry lignocel-

lulosic biomass can be approximated by CH

1.47

O

0.57

. Gasification of lignocellulosic biomass

leads to

CH

1:43

O

0:57

þð0:43 þ 2n

o

2

Þ

H

2

O

n

o

2

O

2

/

CO

þð1:145 þ 2n

o

2

Þ

H

2

(5.32)

Search WWH ::

Custom Search