Biomedical Engineering Reference

In-Depth Information

The residence time varies with temperature and pressure, besides the feed flow rate. There-

fore, the residence time is not an easy parameter to use when designing and/or operating

a reactor.

To simplify the calculation of a time scale, a space time

is defined. The space time is

the time needed to feed a reactor full of reaction mixture through the reactor. It is thus

defined as the total volume of the reactor divided by the inlet volumetric flow rate.

That is,

s

V

Q

0

s

¼

(5.3)

The space time is especially useful for liquid reactors. Since the density of liquids is relatively

constant, we can assume that the flow rate remains nearly constant. In this case, the space

time is nearly the same as the residence time.

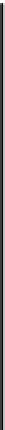

Figure 5.2

shows the space time scale for a variety of important industrial reactions. One

can observe that the required space time is nearly inversely exponentially related to the reac-

tion temperature. Higher temperature requires significantly shorter reaction time.

Alternatively, one can define the frequency of reaction mixture being treated based on the

reactor. This is commonly called space velocity. In bioreactions, the biocatalysts are kept in

10

6

Fermentation

10

5

10

4

Pulping

Hot-Water Extraction

10

3

10

2

Hydrogenation

Fischer-Tropsch

CH

3

OH

10

1

EO

FCC

Maleic anhydride

Steam Reforming

10

0

C

4

dehydrogenation

Automotive converter

CH

4

coupling

10

-1

HCHO synthesis

10

-2

NH

3

oxidation

10

-3

0

200

400

600

800

1000

1200

T,

°C

FIGURE 5.2

Nominal space time required for several important industrial reactors vs the nominal reactor

operating temperatures. Time scale goes from days (fermentation or bioreactions) down to milliseconds (for

ammonia oxidation to form nitric acid). The low-temperature (

T

200

C) long-time (

10 min) processes involve

liquids and/or solids as substrates, while the high-temperature short-time processes involve gases, usually at high

pressures.

<

s

>

Search WWH ::

Custom Search