Biomedical Engineering Reference

In-Depth Information

biorefinery plays a key role in ensuring the cycle of biomass production and consumption

included satisfying human needs for energy and chemicals.

A biorefinery integrates a variety of conversion processes to produce multiple product

streams such as transportation liquid fuels, steam/heat, electricity, and chemicals from ligno-

cellulosic biomass. Biorefinery has been identified as the most promising route to the creation

of a sustainable bio-based economy. Biorefinery is a collection of the essential technologies to

transform biological raw materials into a range of industrially useful intermediates. By

producing multiple products, a biorefinery maximizes the value derived from a lignocellu-

losic biomass feedstock. A biorefinery could produce one or more low-volume high-value

chemical products together with a low-value, high-volume liquid transportation fuel, while

generating electricity and process heat for its own use and/or export.

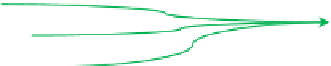

Figure 1.3

shows a schematic of various biorefinery processes. There are two major cate-

gories or approaches in biorefining: biochemical or systematical disassembling processes

and thermochemical processes. In biochemical processes, the lignocellulosic biomass is

commonly disassembled to individual components systematically for optimal conversions

that followed. The basic approach is based on a systematical disassembling and conversion

to desired chemicals. The biochemical processes depend heavily on separation and/or phys-

ical fractionation of the intermediates as well as the final desired products. Biological conver-

sions are preferred over chemical conversions due to their selectivity or green chemistry

concepts. However, owing to the complexity of the lignocellulosic biomass, a multitude of

Oil

Biodiesel

Enzymatic hydrolysis

Inulin

Amylose

Biochemicals,

bioploymers,…

Thermal-

Mechanical

Pretreatment

Amylopectin

Acetic acid

Ethanol

Extractive

Acids

Enzymatic

hydrolysis

Butanol

Acetone

Hemicellulose

Thermal-

Mechanical

Pretreatment

Sugars

Cellulose

Hydrogen

Aromatics

PHA

Pyrolysis oil

“Coke”

Adhesives

Cellulose or

paper products

Or biopolymers

Pyrolysis

Surfactants

…

Volatiles

Thermal-

Mechanical

Pretreatment

H

2

, CO

Syngas

Chemicals

Catalytic synthesis

Liquid fuels

or fermentation

Condensates

Gasification

Electric Power

“Coke”

Burning / CHP

Heat / steam

FIGURE 1.3

A schematic of various biorefinery processes (with permission: S. Liu, Z. Zhang, and G.M. Scott.

2010 “The Biorefinery: Sustainably Renewable Route to Commodity Chemicals, Energy, and Materials”, J. Biotech.

Adv. 28:542).

Search WWH ::

Custom Search