Biomedical Engineering Reference

In-Depth Information

Q

0

,

C

0

,

T

0

C

,

T

Q

,

C

,

T

C

,

T

C

,

T

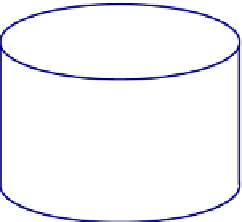

FIGURE 3.12

Schematic diagram of a CSTR or chemostat showing one stream flowing in and one stream

flowing out of the reactor, with proper volumetric flow rates, temperature, and concentrations.

in Chapters 9, 14, and 16, that catalysts and/or microorganisms could change with time after

extended time of exposure in the reactor. Nonideality can arise despite the conditions of flow

and mixing being ideal. Therefore, controlling the flow rate alone cannot maintain all the

parameters to be invariant with time for a CSTR operation in practice. Especially for bio-

reactions, the variation of some parameters or quantities can be significant. Therefore, depend-

ing on the different set goals of maintaining different parameters in the reactor and/or in the

effluent, different terminologies of “steady” bioreactor are used. For example, the commonly

used term chemostat stands for “chemical environment being static.” Other examples include

Turbidostat

d

Turbidity being static. If chemical species do not change, the change of

turbidity is associated with the change of cell biomass concentration. Therefore, tubidostat

is intended for an operation of steady cell biomass.

Cytostat

d

Cell biomass being static in the reactor.

pH-auxostat

d

pH values being static in the reactor.

Productostat

d

The concentration of a key metabolic product being static in the reactor.

3.16. BIOPROCESS SYSTEMS OPTIMIZATION

We have covered the reactor mass and energy balances so far. Next, we consider the

overall economic performance as it will dictate how or whether the bioprocess will be in

operation. At least in a short-time scale, a process that makes money or a profit is a

process that creates value. Therefore, every process engineer would like to make sure the

process he/she is working on is making a profit. The profit is a net accumulation of value

from a process. The profitability of a process is strongly dependent on

(1) Reactor operating cost (RO$). This includes the utility (solvent use, energy, equipment

depreciation, etc.) cost and labor cost that associated with operating the reactor or

reactors. For bioprocess operations, we normally related the reactor operating cost to

the size of the reactor, the throughput, and the intended temperature of operation,

i.e. OP$

f(V, Q

0

, T). Here is Q

0

the volumetric flow rate of raw material feed into

the reactor.

¼

Search WWH ::

Custom Search