Environmental Engineering Reference

In-Depth Information

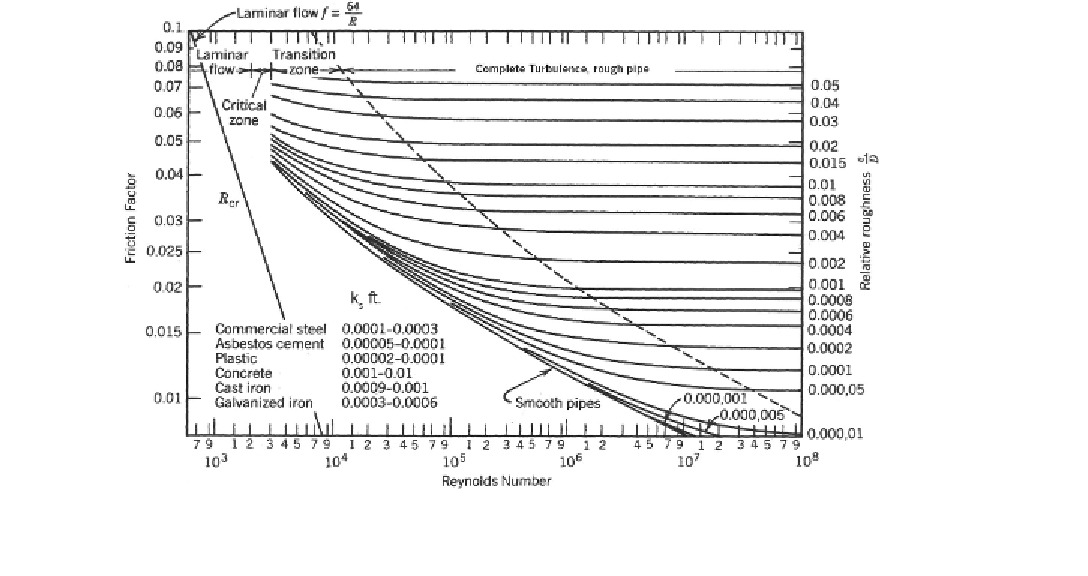

Figure 9.3

Moody diagram

pipe wall roughness typically varies during the life of the pipe as a result of pipe

wall material removal and deposition, mineral deposition, or growth of organic

matter. Manufacturing methods also cause variations in the surface roughness.

The representative values of

k

s

listed in Figure 9.4 should be considered approxi-

mate (consult pipe manufacturer) and proper allowance should be made for these

uncertainties.

To determine

f

using the Moody diagram (Figure 9.3), Re and

k

s

/D

must

be known. Re can be calculated directly if the water temperature,

Q

,and

D

are known. The problem then becomes obtaining a good value for

k

s

. If either

the

Q

or

D

is not known, the solution to the Darcy-Weisbach or Swamee-Jain

equations require a trial-and-error or iterative solution.

For long gravity-flow pipelines, the criterion for pipe diameter selection is

simply finding the smallest pipe that can pass the required flow rate without the

friction and minor losses exceeding the available head. The required flow rate

for design should consider both current and future demand considerations. For

pumped systems, optimizing the pipe diameter is based on an economic analysis

that compares the installed pipe cost with the cost of building and operating the

pumping plant. Pipe cost is proportional to

D

and friction loss, which is related

to the required pumping head and operating cost, is inversely proportional to

D

. The optimum pipe diameter is selected as the one that provides the lowest

total cost.

Search WWH ::

Custom Search