Environmental Engineering Reference

In-Depth Information

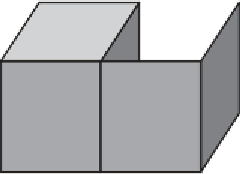

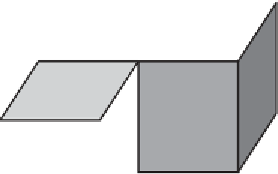

Figure 1.3

Honeycombing loss

number of storage spaces that are next closest to the I/O point, and so on.

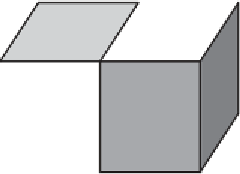

Figure 1.4 shows an interactive

playspace

in the “Ten principles of Mate-

rials Handling” CD that allows a learner to understand the fundamental

concepts of the COI policy.

2.7

System

A

system

is a collection of interacting or interdependent entities that form a

unified whole. Material movement and storage activities should be fully inte-

grated to form a coordinated operational system that spans receiving, inspection,

storage, production, assembly, packaging, unitizing, order selection, shipping,

transportation, and the handling of returns. Here are five key aspects of the

system principle:

1.

Systems integration should encompass the entire supply chain, including

reverse logistics. It should include suppliers, manufacturers, distributors,

and customers.

2.

Inventory levels should be minimized at all stages of production and

distribution, while respecting considerations of process variability and

customer service.

3.

Information flow and physical material flow should be integrated and

treated as concurrent activities.

4.

Methods should be provided for easily identifying materials and products,

for determining their location and status within facilities and within the

supply chain, and for controlling their movement. For instance, bar coding

is the traditional method used for product identification. Radio frequency

identification (RFID) uses radio waves to automatically identify objects as

Search WWH ::

Custom Search