Biomedical Engineering Reference

In-Depth Information

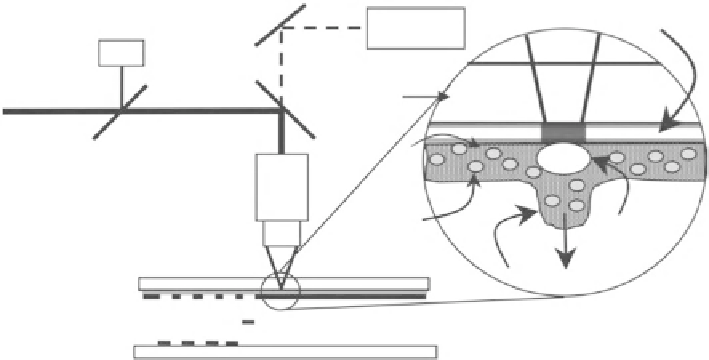

Laser Absorption Layer

Energy meter

CCD Camera

Support Layer

Laser

Biological

Layer

Microscope

Objective

Cells in Fluid

Biolayer

Material Transfer

Ribbon

Substrate

Fig. 9.9

Schematic illustration explaining the working principle of BioLP. A focussed laser beam

initiates material transfer towards the substrate. Interestingly, a laser absorption layer prevents

direct interaction between the laser and the biological materials. The scheme was reused from

[

277

] with the permission from Springer

methods have been described [

266,

268,

287,

291

]. In a post-processing step, the

construct is transferred to a bioreactor and the bio-ink spheres are fused. The

bio-paper, a hydrogel, can be removed after construction if required. Bio-printers can

either have a jet design or work like a mechanical extruder [

101,

293

] . This implies

that several RP apparatuses described in the previous part can serve as a bio-printer

(e.g. the Bioassembly Tool, 3D-Bioplotter™, …), if sterile conditions can be

acquired. In the case of inkjet technology, individual or small cell clusters are printed.

Despite the advantageous speed, versatility and cost, high cell densities are difficult

to obtain and considerable cell damage is induced [

266,

293

]. On the other hand,

extrusion-based bio-printers are more expensive but offer a more gentle approach

towards cells.

In this context, hydrogels are employed as bio-paper and only provide a tempo-

rary support for the deposited bio-ink particles. In other words, the bio-paper is

clearly different from scaffolds used in classical scaffold-based TE. In most cases,

this bio-paper hydrogel will have a sheet-like design (e.g. Fig.

9.10

). For instance,

Boland et al. [

294

] made use of thermo-sensitive gels to generate sequential layers

for cell printing. The group developed a cell printer, derived from commercially

available ink-jet printers [

295

], that enables to place cells in positions mimicking

their spatial location in an organ. The printer can put up to nine solutions of cells

or polymers into a specific place by the use of specially designed software, and

print two-dimensional tissue constructs. Extending this technology to three dimen-

sions is performed by the use of thermo-reversible gels. These gels were a fluid at

20°C and a gel above 32°C and serve as bio-paper on which tissue structures can

be printed. Dropping another layer of gel onto the already printed surface could

generate successive layers. The thermo-sensitive gel used for the experiments was

Search WWH ::

Custom Search