Biomedical Engineering Reference

In-Depth Information

Scanner system

(XY-movement)

V

2

Fabrication platform

Fabrication platform

Laser

V

2

Liquid photocurable

resin

Coated glass slide

Lens

Liquid photocurable

resin

Laser

Digital Mirror Device

(DMD)

BOTTOM-UP

TOP-DOWN

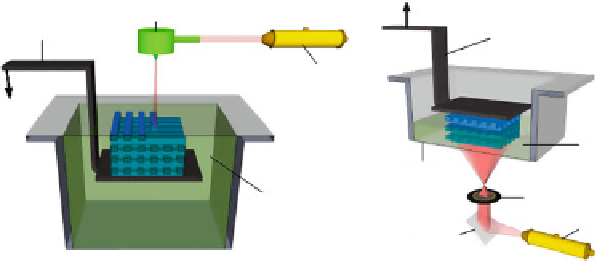

Fig. 9.3

Scheme of bottom-up (

left

) and top-down (

right

) stereolithography set-ups. The bottom-

up set-up shown, is an example of a system whereby the laser scans the surface for the curing of

the photosensitive material. In the example of the top-down set-up, dynamic light projection tech-

nology is used to cure a complete 2D layer at once

(commonly UV light), a system that controls the xy-movement of the light beam and

a fabrication platform that permits movement in the vertical plane. Scanning the sur-

face of the photosensitive material produces 2D patterns of polymerized material

through single photon absorption at the surface of the liquid material. The build-up of

a 3D construct is made possible using a layer-by-layer approach, whereby the fabrica-

tion platform moves stepwise in the

z

-direction after a 2D layer is finished. The step

height of the fabrication platform is typically smaller than the curing depth, ensuring

good adherence of subsequent layers. Post-treatment steps involving washing off

excess resin and further curing with UV light are in most cases necessary. Arcaute

et al. [

132

] demonstrated the possibility to alter the resolution of the cure depth by

varying the laser energy, the concentration of poly(ethylene glycol) dimethylacrylate

(PEG-DMA) as photocrosslinkable material and the type and concentration of the

photoinitiator. In addition, adjusting the scanning speed influences the cure depth.

Micro-stereolithography (m -SLA)

. The working mechanism of m-SLA can be con-

sidered the same as that of a normal SLA. The difference between both involves the

resolution of the system. m-SLA systems are typically able to build very accurately

(a few microns) objects of several cubic centimetres [

133-

136

] .

Figure

9.3

(left) shows a scheme of the so-called bottom-up set-up, in which an

object is built from a fabrication support just below the resin surface. Subsequent

layers are being cured on top of the previous layers by irradiation from above.

Although to date this is the most applied set-up [

132,

134-

139

] , a top-down

approach (Fig.

9.3

right) is gaining interest [

70,

131,

133

] . Top-down set-ups have

a non-adhering, transparent plate acting as the bottom of the liquid reservoir.

Polymerization of the photosensitive material occurs through irradiation from

underneath, and the fabrication platform moves in the opposite direction as in the

bottom-up approach. In this way, every newly formed layer is located beneath the

previous one. Separating every newly formed layer from the bottom plate will

Search WWH ::

Custom Search