Biomedical Engineering Reference

In-Depth Information

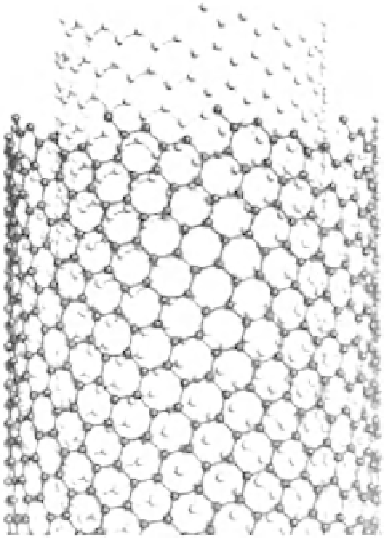

Fig. 8.7

Helical arrangement

of carbon atom hexagons that

make up a graphene sheet in

a MWCNT [

40

]

Wong et al. [

97

] provided an insight into the potential applications of CNT.

Atomic force microscopy (AFM) was employed to determine the elasticity, strength

and toughness of individual silicon carbide (SiC) nanorods and MWCNT that were

attached to molybdenum disulphide surfaces. The average bending strength of the

MWCNT was 14.2 ± 8.0 GPa, with the maximum bending strength being substan-

tially smaller than that of the SiC nanorods at 53.4 GPa. In contrast, whilst both

nanostructures exhibited high values for Young's modulus (highlighting their suit-

ability as reinforcing agents in ceramic, metal and polymer matrix composites) the

Young's modulus for the MWCNT was almost double that of the SiC nanorods

(1.28 ± 0.59 TPa and ~600 GPa, respectively). The Young's modulus value for the

in-plane modulus of highly orientated pyrolytic graphite was recorded at 1.06 TPa

[

9

] and is believed to be the largest known for a bulk material. Wong et al. [

97

]

concluded that while the stiffer MWCNTs had a lower ultimate strength, the elastic

buckling displayed by the MWCNTs (i.e. the energy storing capabilities of CNT

before failure) showed them to be the “tougher” nanostructure. More recently,

Demczyk et al. [

18

] investigated the direct failure of individual MWCNT under ten-

sion using TEM. While the mode of failure, either ductile or brittle, could not be

determined, results confirmed a tendency to fail via a mode now known as “tele-

scopic failure”, with initial failure observed in the outermost walls followed by a

“sword in sheath effect” of the inner cylinders. These TEM observations also

confirmed the elastic capabilities of MWCNTs during deformation in bending, even

after being highly distorted.

Search WWH ::

Custom Search