Biomedical Engineering Reference

In-Depth Information

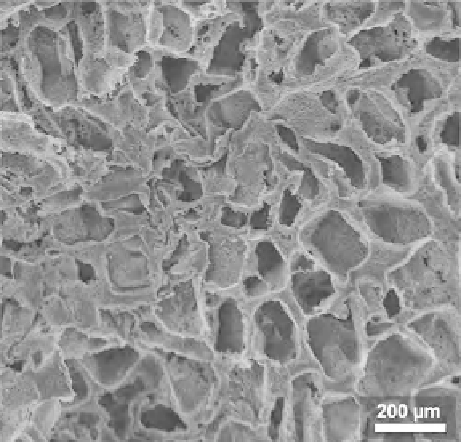

Fig. 1.2

Scanning electron

microscopy of PCL scaffolds

obtained by phase inversion

and salt leaching technique

In particular, the synergic combination of phase inversion/salt leaching tech-

nique and the filament winding technology allows developing composite scaffolds

incorporating polylactide (PLA) continuous fibers within a PCL matrix which sat-

isfy these requirements [

17,

18

]. The employment of highly biocompatible and

bioresorbable PCL and PLA assures the maintenance of sufficient physical and

mechanical properties for at least 6 months before their degradation. The integra-

tion of a solid porogen (i.e., sodium chloride crystals) within a 3-D polymer matrix

enables creation of an interconnected pore network with well-defined pore sizes

and shapes (Fig.

1.2

).

Tricalcium phosphate (a-TCP) powder, which is able to precipitate in calcium-

deficient hydroxyapatite (CDHA) form, is recognized by the host tissue as being

similar to natural bone apatite. Moreover, it significantly hinders the stress-shielding

phenomena associated with the use of traditional rigid metal-based implants.

Meanwhile, the continuous degradation of the implant causes a gradual load

transfer to the healing tissue, preventing the stress-shielding atrophy, with the stim-

ulation of the healing and bone remodeling. The balance between chemical compo-

sition and spatial organization of reinforcement systems allows attaining an optimal

compromise between mechanical response and bioactive potential to reproduce the

bone mECM features.

1.3.2

Multi-scale Degradation

To date, much effort has been dedicated to the design of a variety of composite

materials for tissue engineering scaffolds with tailored degradation properties.

Search WWH ::

Custom Search