Biomedical Engineering Reference

In-Depth Information

Analysis of retrieved bioresorbable interference screw confirmed that future

research should be directed to the improvement of material properties using new

composite materials (e.g., hydroxyapatite components which facilitate the bone

in-growth). Attention should be given to the screw self-tapping design which will

assure reduction of breaking forces and avoid damaging the soft tissues, espe-

cially the of the reconstruction graft.

6.3.2

Innovative Design of a Bioresorbable Interference Screw

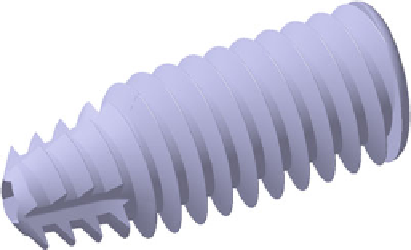

Based on clinical experience and finite element simulations, a new bioresorbable

interference screw design is proposed. The self-tapping interference screw has the

following main design particularities (Fig.

6.11

):

•

The shape of the screw is cylindrical at the proximal end and tapered at the distal

end for approximately one-third of the whole screw length.

The thread depth of 1.5 mm (for a screw of 10 mm diameter) for the proximal

•

cylindrical zone, progressively decreasing along the conical zone.

The shape of the thread differs for the cylindrical and tapered zones; the passage

•

from a shape of the thread to the other is made progressively, no sharp edges

being generated; double-helix thread with constant pitch of 2 mm.

Hexagonal interior channels with different dimensions for the cylindrical and

•

conical zones.

Three cutting flutes uniformly distributed on the conical part of the screw.

•

•

Proximal rounded thread edges.

Different designs of the interference screw were obtained by varying the attack

angles (the first angle of the thread flank in the insertion direction) for the distal and

proximal zones (25°/30°, 25°/40°, 30°/30°, 30°/40°). In order to assess the influence

of these angles on the screw holding strength, several FE simulations were per-

formed using ANSYS v12 software (Figs.

6.12

,

6.13

,

6.14

,

6.15

,

6.16

, and

6.17

).

The maximum displacement for each screw design and the equivalent von Misses

stresses were calculated in a static structural analysis in which the tendon was loaded

along the tunnel axis at 200N, according to the data presented in literature [

74

] .

Fig. 6.11

3D CAD model of the

innovative interference screw

Search WWH ::

Custom Search