Biomedical Engineering Reference

In-Depth Information

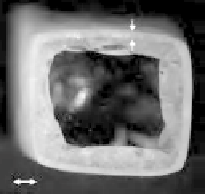

Crystalline surface layer

T

p,a2

T

p,a1

T

p,b

10 mm

frit

powder

T

g

400

450

500

550

600

650

700

Temperature (

°

C)

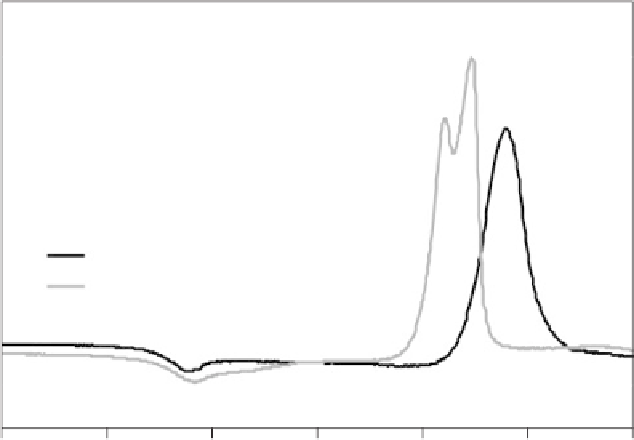

Figure 4.12

DSC traces of frit (particle size about 1 mm) and fine powder of a phos-

phate invert glass in the system P

2

O

5

-CaO-MgO-Na

2

O-TiO

2

with 34.8 mol%

P

2

O

5

. Traces show glass transition (

T

g

) and crystallisation temperatures (

T

p,a1

,

T

p,a2

and

T

p,b

). Inset shows surface crystallisation on glass monolith after heat

treatment for 30 minutes at 540

◦

C.

When comparing the DSC traces of frit (i.e. particles obtained by

quenching the glass melt in water) and milled fine powder of a phosphate

invert glass (34.8 mol% P

2

O

5

) in Figure 4.12, two main differences are

obvious: the crystallisation peak of the fine powder appears at a lower

temperature than that of frit; and it actually consists of two overlapping

peaks, compared to only one visible peak for glass frit. The reason for

the double peak is that the glass crystallises into two different phases

(identified as calcium pyrophosphate, Ca

2

P

2

O

7

, and a mixed calcium

magnesium pyrophosphate, CaMgP

2

O

7

), which are resolved as separate

peaks in the DSC trace of fine glass powder but not for glass frit. The

decrease in crystallisation temperature with decreasing particle size (from

coarse frit to fine powder), on the other hand, often suggests a surface

crystallisation mechanism. Surface crystallisation means that, upon heat

treatment, the crystals start growing from the outer surface of the glass

towards the centre, rather than throughout the bulk of the material

as in volume crystallisation. Indeed, if a glass monolith of the same