Biomedical Engineering Reference

In-Depth Information

− +

H

H

+ −

H

+ −

H

+ −

− +

H

H

+ −

×

4

− +

H

− +

H

H

+ −

− +

H

− +

H

H

+ −

− +

H

− +

H

H

+ −

H

+ −

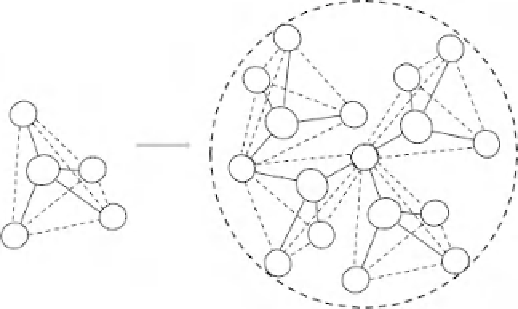

Figure 3.4

A schematic of silica tetrahedra forming a nanoparticle in a sol. The

nanoparticle will coalesce with other similar particles and bonds will form between

them to form a silica network. When it becomes rigid, it will be a gel.

The hydrolysis and polycondensation reactions occur simultaneously

within the solution during mixing. When sufficient interconnected

Si-O-Si bonds are formed in a region, they behave as colloidal (sub-

micrometre) particles and a sol is formed (Figure 3.4). The first small

particles that form are termed 'primary particles'.

3.4.2 Stage 2: Casting

The sol can be cast prior to gelation in air-tight moulds. The moulds

must be made of material that will not adhere to the gel (e.g. polyte-

trafluoroethylene, PTFE). The gelation process can take several days at

room temperature but can be tailored to the needs of the process.

3.4.3 Stage 3: Gelation

As mixing continues, agglomeration of the primary particles occurs and

condensation continues, causing coarsening of the particles. As more

and more particles join together, a network of O-Si-O bonds begins to

form, the viscosity of the sol increases and eventually a gel (rigid silica

network) is formed. The reaction continues until all the precursor is

used up.

3.4.4 Stage 4: Ageing

After gelation, the gel is aged, either at room temperature or at slightly

elevated temperatures, for example 60

◦

C, for several hours or days.