Biomedical Engineering Reference

In-Depth Information

Oxygen

Microsphere

Collection

Barrel

Acetylene/oxygen flame

Flame Sprayer

REAS Glass

Microspheres

REAS Glass

Particles

Acetylene

REAS Glass Powder in N

2

Gas

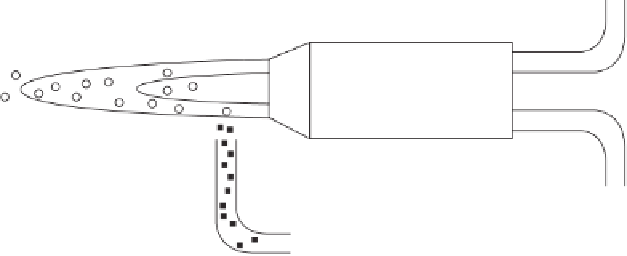

Figure 13.3

Schematic of the system used to produce glass microspheres by

spheroidizing a glass powder in a gas burner (flame spheroidization). (Reprinted

with permission from [4]. Copyright (1994) Trans Tech Publications.)

REAS glasses form over a fairly broad compositional range in each

system, which is a desirable feature. Note also that these glasses can

contain large amounts of the various RE oxides, from a low of 32wt%

to a high of 69wt%, depending upon the specific RE oxide. Yttrium,

while not strictly a RE, is included in Figure 13.2 since its properties are

close to those for the RE elements.

To make microspheres, the glass is crushed to a powder of the

generally desired size and the powder is feed to a gas burner as shown

in Figure 13.3. The glass particles melt in the flame and the molten

droplets become spherical (Figure 13.1b and see Figure 15 in colour

section) owing to surface tension. After cooling, the microspheres are

screened to the exact size needed for the specific application. Many of

the REAS glasses can also be pulled into fibers ranging in diameter from

10 to 5000

μ

m.

13.3.2 Properties

As would be expected, the properties of REAS glasses depend some-

what upon the particular RE element present in the glass. Some selected

properties for REAS glasses containing yttrium (Y), samarium (Sm),

holmium (Ho), or dysprosium (Dy) are given in Table 13.1. The

line labeled ''RE

2

O

3

content'' in Table 13.1 denotes the approximate

minimum-maximum amount of RE oxide for each system. The density

of the REAS glasses in Table 13.1 increases with increasing RE

2

O

3