Biomedical Engineering Reference

In-Depth Information

providing local attachment to different parts of the surrounding tissue.

In the ideal implant, the coating compositions must be tailored to provide

local attachment to both the bone and the gum.

The coating was manufactured by dip coating the titanium implants

in a suspension of ethanol and powdered glass (

m). Then the

glass particles were sintered with a focused CO

2

laser beam to a

coating that consists of micro-sized (diameter

<

45

μ

∼

m) glass drops

[14]. The glass composition used, 1-98, is optimised to show a lower

tendency to crystallisation in thermal treatments than 45S5 glass and

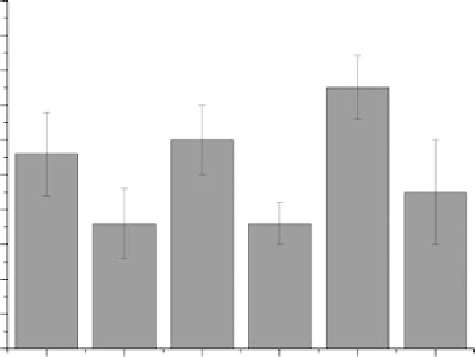

S53P4 glass. Moritz and co-workers compared the osteointegration of

the bioactive glass-coated titanium implants with titanium implants in

rabbit femur. After eight weeks, the implants coated with the bioactive

glass were covered with significantly more bone tissue than the totally

titanium implants (Figure 11.6). In the area spread 250

60

μ

mfromthe

perimeter of the implant, significantly more bone was observed in the

implants with the bioactive glass coating than in the two non-glass-

coated implants. In the area spread 1mm from the perimeter of the

implant, no statistically significant difference between the materials was

detected, although slightly more bone had formed around the implants

coated with the bioactive glass. The results all indicate that bioactive

glass coatings on titanium implants enhance the initial osteointegration.

μ

100

90

80

70

60

50

40

30

20

10

0

NaOH 1

NaOH 2

BG 1

BG 2

Ti 1

Ti 2

Implant material

Figure 11.6

Amount of bone tissue in proximity of the implant after eight weeks

in rabbit femur for titanium alloy, NaOH-treated titanium alloy and bioactive glass

coated titanium. 1: 250

μ

m; 2: 1mm. (Drawn from data obtained from Ref. [14].)