Biomedical Engineering Reference

In-Depth Information

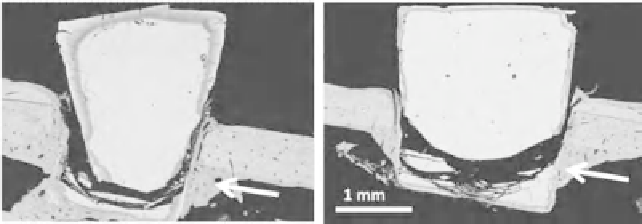

(a)

(b)

Figure 11.2

Cross-sections of cones of (a) 45S5 glass and (b) S53P4 glass after

eight weeks in rat femur. The arrows point out the new bone. (Expanded view of

Figure 11.2 in [3]. Copyright (2010) Society of Glass Technology.)

good contact with the bone, as indicated by the implant failure within

the glass.

Glass composition has a great effect on bioactivity and processability.

Chapter 2 described the effect of silica content on bioactivity and how

network modifiers could be replaced with others to change properties;

for example, replacing calcium oxide with strontium oxide has been

found to enhance bone formation.

The number of different network modifiers can also be changed. To

make porous glasses (Chapter 12), coatings (Chapter 8) or fibres from

melt-derived glasses, the glasses have to be worked above their glass

transition temperature. The low silica content and high lime content of

the first bioactive glasses make them prone to crystallise when they are

above the glass transition temperature. This is the reason why current

commercial bioactive glasses are mainly particulates. Glasses containing

more oxides can increase the temperature difference between the glass

transition temperature and the crystallisation onset temperature, creating

a wider operating window. K

2

O, MgO, B

2

O

3

and Al

2

O

3

can be added

to the glasses [2, 4, 5] to do this. The compositions of the studied glasses

were chosen with the help of statistics, thus enabling the modelling of

the measured properties as functions of the oxide composition of the

glass. Today, models of

in vitro

and

in vivo

reactivities as well as models

of the hot working properties are available [2, 4-6]. These property

models can be utilised to tailor compositions for controlled reactivity in

any product form desired.