Biomedical Engineering Reference

In-Depth Information

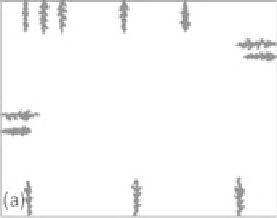

Figure 7.2

Controlled crystallization on the surface of the base glass in the

development of glass-ceramics: (a) nucleation and (b) growth. (Reprinted with

permission from [2]. Copyright (2006) W. Holand.)

desired size, the base glass is cooled down to stop them from growing

further. The condition of the glass that has been achieved and the size

of the crystals is preserved by freezing the material. This is how the

microstructure of glass-ceramics is produced.

In the next section, we will look at different glass-ceramics with

very special characteristics. We will explain their chemistry, describe

the components that are used to start the crystallization process, and

examine the crystallized parts of the material, which are responsible for

producing the special characteristics of the glass-ceramic.

7.3 A GLASS-CERAMIC THAT HARDLY EXPANDS

WHEN HEATED

The combination of SiO

2

-Al

2

O

3

-Li

2

O is suitable for making glass,

which can be used to produce glass-ceramics that hardly expand when

they are heated. This is important when making precision shapes, as the

amount of expansion of other systems is difficult to control to exact

measurements. These three oxides form what is called a glass formation

system and can be supplemented with a wide range of other chemi-

cal compounds. The substances that cause the crystallization process

(nucleating agents) are the most important compounds. TiO

2

and ZrO

2

are usually used for this purpose. When the base glass is heated, these

compounds react and form a first crystal structure on which the desired

crystal structure then grows when the glass is heated again. Over many

years, researchers in the USA, Europe, and Japan developed crystalliza-

tion processes in which SiO

2

mixed crystals (also called solid solutions)

could be produced. The main aim of their work was to produce an SiO

2

crystal structure that would not expand when the material was heated