Biomedical Engineering Reference

In-Depth Information

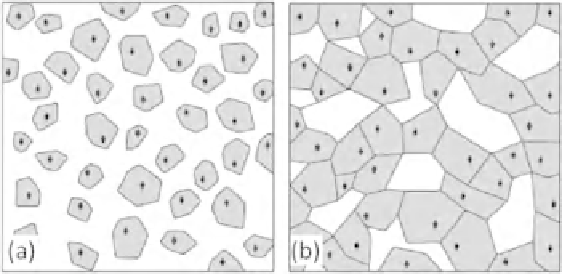

Figure 7.1

Controlled internal crystallization in glasses for producing glass-

ceramics: (a) nucleation of crystallites in a glass; and (b) crystals grow and join

at grain boundaries. (Reprinted with permission from [2]. Copyright (2006) W.

Holand.)

In internal nucleation and crystallization, centers, or nucleation sites,

from which the crystallization process starts are required. These sites are

formed by chemical compounds that are added to the base glass. The

chemical compounds, which are called nucleating agents, speed up the

beginning of a process. We will explain what these nucleating agents are

all about in the next few paragraphs. These substances form a crystalline

phase, a foreign substrate, on which the actual crystal phase grows. This

phenomenon is shown in Figure 7.1.

Glass-in-glass phase separation provides another way of starting the

internal crystallization process within a base glass. During the separation

of the glass into different phases, specific ions are concentrated into one

phase, which enables nuclei and then crystal to form.

In addition to the method involving internal crystallization, the

process of surface nucleation and crystallization is used to produce

glass-ceramics. A diagram of the mechanism is shown in Figure 7.2.

Glass is crushed to form a powder, and the surface of the glass powder

grains is activated to produce crystals. These crystals then proceed to

grow inwards from the surface of the glass particles.

For both methods to work, the chemical composition must be just

right, and the base glass has to be heated to a very high temperature in

the region of 1000

◦

C. By heating the glass, the processes of nucleation

and crystallization are started and kept under control. The thermal

energy (heat) makes molecules move around in the base glass and

stimulates the growth of crystals in very specific areas. This is clearly

shown in Figures 7.1 and 7.2. When the crystals have reached the