Environmental Engineering Reference

In-Depth Information

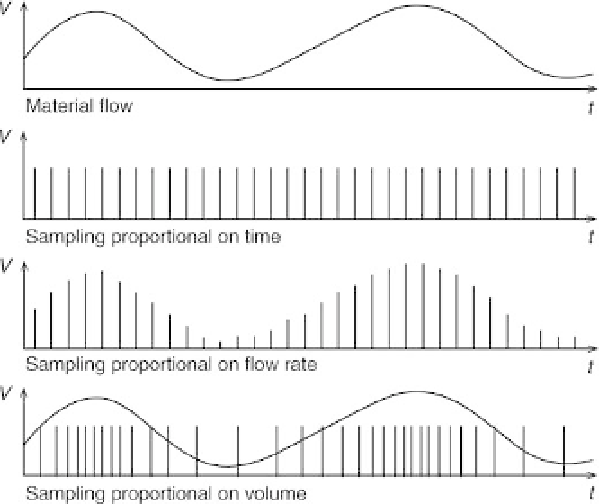

3.4 Sampling with different flow rates and material composition

(source: Schwedt G (2007) Taschenatlas der Analytik. Wiley-VCH,

Weinheim, Germany; Figure E on p.19; copyright Wiley-VCH Verlag

GmbH & Co. KGaA; reproduced with permission).

least one sample should be drawn from every phase. These samples can then

be mixed together according to the quantity of the phases. If the material is

very inhomogeneous and no phases can be located, samples should be

drawn from different locations and depths of the material. They can also be

put together as a mixed sample.

For solid material, a representative sample can be obtained using the

following procedure. With a spade or a sampling device, a large sample is

taken from the material. This large sample is spread onto a clean surface

and then mixed well. A cross is then drawn through the middle of the spread

sample and two opposite quarters are removed. The remaining two quarters

are spread and mixed again and again a cross is drawn and two quarters

removed. This process is repeated until the required amount of sample is

obtained.

For liquid material, the liquid has to be stirred well before sampling. The

sample bottle should then be submersed into the liquid for sampling. If a

sampling valve is used, the first material leaving the valve should be rejected

to allow cleaning of the sampling valve. If a sample is taken from a pipe

where the material passes at different flow rates and with different

composition, a sample proportional to flow rate or volume can be taken

(Fig. 3.4). Automatic sampling devices can be used for this purpose. In

Search WWH ::

Custom Search