Environmental Engineering Reference

In-Depth Information

17.4

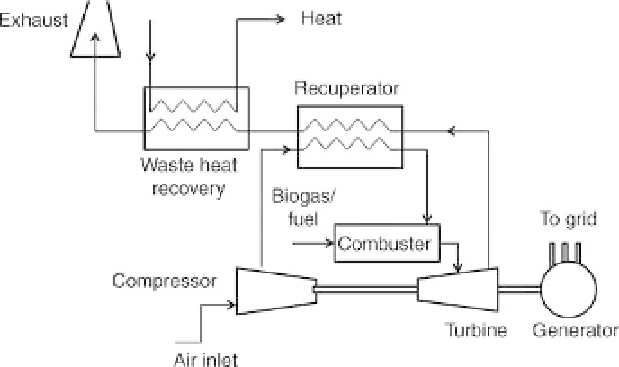

Gas turbine process with heat recovery (adapted from Deublein

and Steinhause, 2008, with permission from Wiley-VCH Verlag & Co.

KGaA, Germany).

heating the air that is sucked in (Fig. 17.4). Commercial units can range in

size from 500 kW to 250MW. A single-cycle turbine has an efficiency of 20-

45% at full load, with efficiency increasing with size (Chambers and Potter,

2002). The electrical capacity, and thus the efficiency of the gas turbine, can

be increased by changing the amount of biogas supplied to the combustion

chamber or increasing the turbine inlet temperature.

Gas turbines are available in medium to large capacities and are

characterised by low emission values. When fed with cleaned biogas, the

NO

x

emission in the exhaust gas is less than 25 ppmv (Deublein and

Steinhause, 2008). The CO content can be considerably reduced by installing

a downstream catalyst.

17.3.8 Generation of electricity in a micro gas turbine

Micro (gas) turbines are small, high-speed, gas combustion turbines with a

power rating of 25-500 kW (Chambers and Potter, 2002). Micro turbines

are considered easy to handle and are relatively low noise and vibration free.

They can use various fuels, including natural gas, biogas, associated gas,

biodiesel and kerosene. Micro turbines are increasingly used for biogas

applications, especially in cogeneration at wastewater treatment plants,

codigestion plants, farms and landfills.

Micro turbines typically comprise an air compressor, combustor, turbine,

alternator, recuperator and generator (Fig. 17.5). Micro turbines have a

single shaft on which the compressor, turbine and generator are fixed. Gas

turbines are single-stage, radial flow devices with rotating speeds of 90 000

to 120 000 rpm (Chambers and Potter, 2002). The turbine propels the

Search WWH ::

Custom Search