Environmental Engineering Reference

In-Depth Information

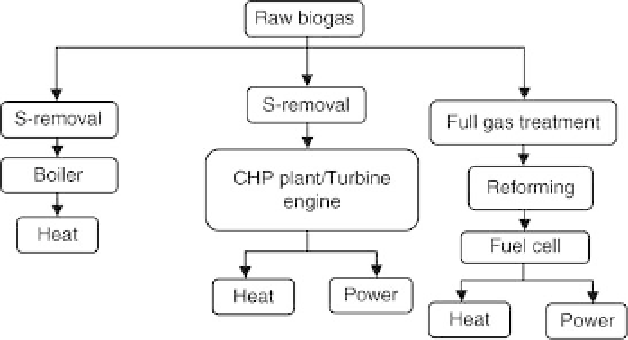

17.1 Use of biogas for various stationary applications (S-removal

represents removal of sulphur compounds).

H

2

S concentration and H

2

S removal is necessary at concentrations higher

than 1000 ppmv (Chambers and Potter, 2002). In comparison to gas engines,

micro turbines are more resistant to sulphur compounds and lower oxides of

nitrogen, NO

x

(refers to NO and NO

2

)) and carbon monoxide (CO)

emissions. Similarly, extensive biogas cleaning is required for the use of

biogas in fuel cells. Components of concern from an emissions and

equipment safety and maintenance point of view are

.

reduced sulphur compounds (H

2

S, mercaptans (CHaSH), dimethyl

sulphide (CH

3

SCH

3

, DMS), carbonyl sulphide (COS) and carbon

disulphide (CS

2

)) due to their contribution to SO

2

emissions, safety

concerns and corrosion due to formation of sulphuric acid

.

compounds containing nitrogen (N

2

) due to their potential to increase

NO

x

emissions and potential to form nitrous oxide, N

2

O (a greenhouse

gas)

.

chlorinated compounds due to the potential to form dioxins during

combustion

.

siloxanes, which on combustion transform to microcrystalline silicon

dioxide (SiO

2

) and deposit on valves, cylinder walls and liners, causing

abrasion and blockage of pistons, cylinders and valves.

17.2.2 Biogas purification

The typical biogas composition from digesters operating in Europe is

presented in Table 17.1. Depending on the source, biogas mainly contains

45-70% CH

4

, 30-55% CO

2

, 0-2000 ppmv H

2

S and 0-590 ppmv NH

3

(Rasi

et al., 2007; Petersson and Wellinger, 2009). H

2

S concentration is strongly

influenced by the composition of feedstock used for biogas production. The

Search WWH ::

Custom Search