Environmental Engineering Reference

In-Depth Information

10.2

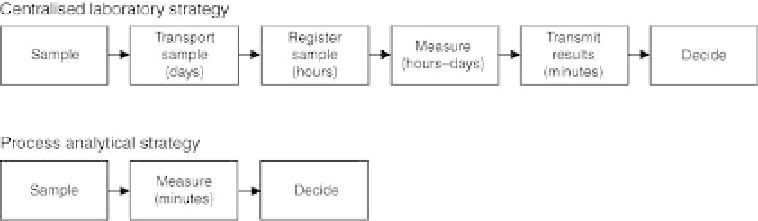

Comparison of analytical strategies for process monitoring.

also widespread in other industries. In 2005, the US Food and Drug

Administration produced industry guidance in which PAT was defined as a

system for designing, analysing and controlling manufacturing through

timely measurements during processing of critical quality and performance

parameters of raw and process intermediates (FDA, 2005). The goal is to

monitor and control the process on-line as early as possible in the process

and in real time at strategically selected process locations with steps that

ensure the quality of the final product. The term 'analytical technology' in

PAT refers to analytical chemical, physical, microbiological, mathematical,

data and risk analysis conducted in an integrated manner. The term 'quality'

of a product has the meaning of the final quality of various industrial

processes; it can either be the concentration, pureness, strength, or similar of

the processed products. According to the FDA guidance 'Quality cannot be

tested into products; it should be built-in or it should be by design'. Product

quality and/or quantity have to be optimised during the ongoing process.

10.3.3 Control strategies: central laboratory versus on-line

control

Traditionally, monitoring and quality control of production processes has

been based on a centralised laboratory approach. Samples are collected

from a process stream and sent to an analysis laboratory where sub-

sampling, sample preparation and chemical analyses are carried out, often

in an optimised manner, allowing multiple samples to be analysed in the

same run. The time span for the primary sampling was taken from the point

of the process stream until the analytical result had been produced and

approved; this could span from several hours to days depending on the

laboratory infrastructure and routine (Mortensen, 2006) (Fig. 10.2).

It is clear from Fig. 10.2 that the analytical strategy has to be changed

from the centralised laboratory approach to the process analytical strategy if

the biogas plant operator wants to benefit from the analytical results and use

them as true process regulation parameters instead of just 'delayed' quality

control parameters. In fact, the quality control task is moving from the

Search WWH ::

Custom Search