Environmental Engineering Reference

In-Depth Information

9.2

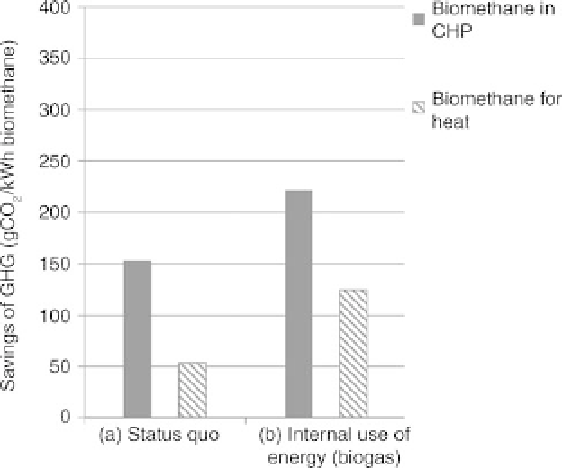

Visualisation of the greenhouse gas balance for use of upgraded

biogas (biomethane) for electricity supply or heat supply. Status quo

(a) assumes that the energy is supplied from electricity mix (Germany)

and heat from natural gas /heat pump (b) shows the greenhouse gas

balance for the same biomethane production plant calculated assuming

that the energy is supplied from biogas. For each, the substrate is

assumed to be energy crops (adapted from Thr ¨ n

et al

., 2011).

supplied in this way. In order to reduce the maximum load of the biogas

plant, the control devices can be programmed so that single components are

never turned on at the same time. If a grid connection is not possible, or is

unreliable, the electricity can be supplied by a biogas-driven local CHP unit.

In this case, a unit designed for a grid-independent start, known as a self-

triggered unit, is necessary. A gas reserve is also required when biogas

production is low and for use when the biogas plant is initially put into

operation when no biogas is being produced. The gas supply can be

obtained either through a natural gas grid connection or through the use of

pressurised gas or liquefied gas (LPG) in bottles or a tank. The CHP unit

must be correctly designed to operate under these conditions; alternatively a

dual-fuel CHP unit can be used, which can run on diesel in situations when

no biogas is available.

Electrical energy losses occur mainly in cables and connectors: the length

of cables should therefore be minimised. Transportation losses of electricity

within a biogas plant can amount to around 1-3% of the energy exported.

Further energy loss can occur in a transformer for different voltages,

typically at the connection point with a local grid. Losses of between 1 and

3% have been documented; the main factor affecting these is the choice of

equipment. Thus, a transformer must be selected that can guarantee low

Search WWH ::

Custom Search