Environmental Engineering Reference

In-Depth Information

8.8

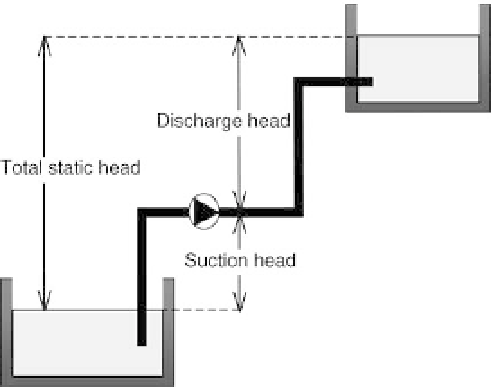

Total static head.

Two main pump groups can be distinguished among those utilised in biogas

plants: centrifugal and displacement pumps. Centrifugal pumps are used for

liquid substrates with dry matter content less than 8%, which is typically the

case for slurry. These pumps are robust and can generate pressures up to

20 bar, but the conveying capacity is strongly dependent on pressure losses

due to the head and friction. In the case of fibrous substrates such as straw,

centrifugal pumps can be equipped with cutters for breaking down the fibres

and thus preventing clogging. A weak suction head is a disadvantage of this

pump type.

Displacement pumps are used for substrates with a higher dry matter

content. They can convey material forwards and backwards, and their

conveying capacity is much less dependent on head and friction. Eccentric

screw pumps, also called progressive cavity pumps, are one type of these

pumps. They function with a metallic rotor in the form of a helix, which

turns eccentrically in a stator with a twin helix. Material can be transferred

at very low flow rates, although high pressures can be generated. A

disadvantage is their sensitivity to impurities, fibres or idle running. Another

type of displacement pump is the rotary lobe pump. Material is trapped in

the cavity of the lobes and is displaced as they rotate. These pumps are

resilient to impurities and fibres and so are frequently used in biogas

installations.

8.4.3 Valves

Valves are used for regulating, directing or controlling the flow. Depending

on the flow media and the specific requirements, different valve types are

employed. The main valve types used in biogas plants are gate valves,

butterfly valves and check valves.

Search WWH ::

Custom Search