Environmental Engineering Reference

In-Depth Information

6.2

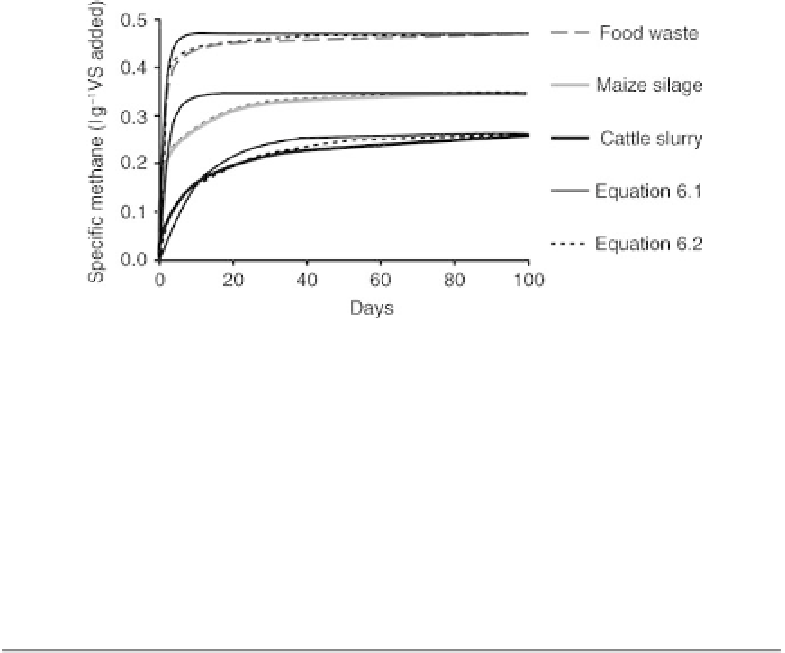

Kinetic models for selected substrates.

Table 6.1

Kinetic parameters from BMP modelling

Parameter values

Food waste

Maize silage

Cattle slurry

Eq. 6.1 Eq. 6.2 Eq. 6.1 Eq. 6.2 Eq. 6.1 Eq. 6.2

max

(l CH

4

g

1

VS added)

Y

0.470

0.470

0.345

0.345

0.260

0.260

P

1

0.88

1

0.60

1

0.33

k

or

k

0.73

1.02

0.44

1.50

0.09

0.50

1

k

0

0.06

0

0.07

0

0.05

2

2

R

0.9874

0.9980

0.9703

0.9987

0.9911

0.9978

fractions. A better fit can be obtained by assuming that the gas production

curve reflects these different rates and properties. Methane production is

therefore given by

e

k

1

t

Þ

e

k

2

t

Y

¼

Y

max

1

P

ð

1

P

½

6

2

:

where Y is the cumulative methane yield at time t, Y

max

is the ultimate

methane yield, k

1

is the first-order rate constant for the proportion of readily

degradable material, k

2

is the first-order rate constant for the proportion of

less readily degradable material and P is the proportion of readily

degradable material. Results for food waste, maize silage and cattle slurry

are shown in Fig. 6.2 and the kinetic coefficients for equations 6.1 and 6.2

are given in Table 6.1. In each case it can be seen that equation 6.2 provides

a better fit. The P values of 0.88, 0.60 and 0.33 reflect the relative

proportions of readily degradable material in food waste, maize silage and

cattle slurry respectively. The decay constant k

2

is similar in all three cases,

but the k

1

values are different. As expected k

1

is higher for food waste than

for cattle slurry as the latter has effectively already undergone a digestion

process. Maize has the highest value of all, reflecting the presence of

fermentation products from the ensiling process that are almost immediately

available for uptake by the methanogenic population.

Search WWH ::

Custom Search