Environmental Engineering Reference

In-Depth Information

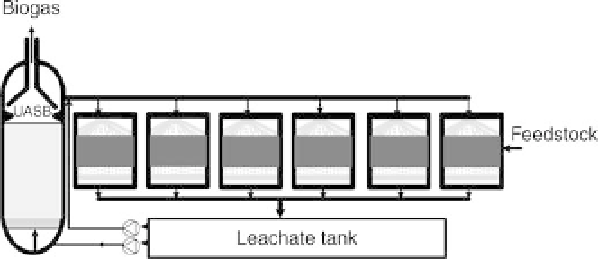

5.5 Sequencing leach bed reactor with upflow anaerobic sludge bed

(UASB) (adapted from Nizami and Murphy, 2011).

5.7

Laboratory analysis and scale up

5.7.1 Single-phase and two-phase systems

This section examines the effect of reactor configuration on the methane

production for a given feedstock (in this case grass silage). High solid

content feedstocks at commercial scale are typically digested in single-phase

systems (all microbiological stages in one vessel). These may be a dry batch

system (Fig. 5.2), a wet continuous system (Fig. 5.3) or a dry continuous

system (Fig. 5.4). Rarely, if ever, are two-phase systems (such as in Fig. 5.5)

employed at commercial scale. Within the scientific literature there are a

number of descriptions of two-phase systems (Cirne et al., 2007; Lehtomaki

and Bjornsson, 2006; Yu et al., 2002), but the authors have yet to encounter

such a system at commercial scale. Potential scale up of two-phase systems

to commercial facilities needs further research and development.

To examine differentiation of single- and two-phase systems, a series of

laboratory experiments was undertaken comparing the same feedstock

(grass silage cut from the same field at the same time) monodigested in

different reactor configurations, as a described by Thamsiriroj and Murphy

(2010), Thamsiriroj and Murphy (2011), Nizami et al. (2011a), Nizami et al.

(2011b) and Nizami and Murphy (2011). The grass silage was analysed (DS

30.66%; 92% of which VS; 19MJ/kg VS; 1 kg of VS produces 1.4 kg COD).

The feedstock was used in a two-step digestion process with recirculation of

liquor (layout similar to Fig. 5.3(b)) and in a two-phase system (Fig. 5.5).

The two-phase system was a sequencing-fed leach bed reactor (SLBR)

complete with upflow anaerobic sludge blanket (UASB). The phases were

separated. Hyrdolysis and acidogensis took place in the leach beds;

methanogensis took place in the UASB reactor (Fig. 5.5).

Search WWH ::

Custom Search