Environmental Engineering Reference

In-Depth Information

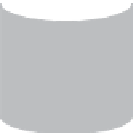

Cellulose

Lignocellulosic

Feedstock (LCF)

Food & feed

Chemicals

Materials

Energy

Hemicellulose

Lignin

Figure 1.7

Simplified diagram of a lignocellulosic feedstock biorefinery.

1.5.2.3.1 Lignocellulose Feedstock Biorefinery

A lignocellulose feedstock biorefinery will typically use lignocellulosic biomass

such as wood, straw and corn stover. The lignocellulosic raw material (consisting

primarily of polysaccharides and lignin) will enter the biorefinery and, through an

array of processes, will be fractionated and converted into a variety of energy and

chemical products (see Figure 1.7).

In the US, ZeaChem is currently developing its first commercial lignocel-

lulose feedstock biorefinery at the Port of Morrow in Boardman, Oregon.

Located adjacent to their demonstration facility, the 25 million gallons per

year integrated biorefinery is expected to produce bio-based fuels, C2 chemi-

cals (acetic acid, ethyl acetate, ethanol and ethylene) and C3 chemicals (pro-

pionic acid, propanol and propylene) from nearby woody biomass and

agricultural residues using a hybrid process of biochemical and thermochemi-

cal processing.

Another example of an imminent lignocellulosic feedstock biorefinery is SP

Processum in Sweden, which corresponds to an integrated cluster of industries

converting wood into energy, chemicals and materials (see Figure 1.8). This is

probably one of the best examples of industrial symbiosis in the world, with one

industry using the waste or by-product of another as a raw material [41]. Among

the member companies are AkzoNobel Surface Chemistry (production of thick-

eners for water-based paints and the construction industry), Domsjo Fabriker

(production of dissolving pulp and paper pulp), Ovik Energy (energy production

and distribution) and Sekab (production of ethanol, ethanol derivatives and

ethanol as fuel).

In reality, while the sole products of existing pulp and paper manufacturing

facilities today are pulp and paper (phase I biorefinery), these facilities are

geared to collect and process substantial amounts of lignocellulosic biomass.

They therefore provide an ideal foundation on which to develop advanced

lignocellulose feedstock biorefineries. Additional processes could be built

around pulp mills, either as an extension or as an 'across-the-fence'-type

company.