Environmental Engineering Reference

In-Depth Information

1.5.2.2

Phase II Biorefinery

Similarly to phase I biorefineries, phase II biorefineries can only process one

feedstock. However, they are capable of producing various end-products (energy,

chemicals and materials) and can therefore respond to market demand, prices,

contract obligation and the operating limits of the plant.

Recent studies have revealed that a biorefinery integrating biofuels and chemicals

offers a much higher return on investment and meets its energy and economic goals

simultaneously [37]. For instance, Wageningen University performed a study in 2010

in which 12 full biofuel value chains - both single-product processes and biorefinery

processes co-producing value-added products - were technically, economically and

ecologically assessed. The main overall conclusion was that the production costs of

the biofuels could be reduced by about 30% using the biorefinery approach [38].

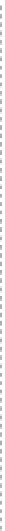

One example of a phase II biorefinery is the Novamont plant in Italy, which

uses corn starch to produce a range of chemical products including biodegradable

polyesters (Origi-Bi) and starch-derived thermoplastics (Mater-Bi). Another

example of this type of biorefinery is the Roquette site of Lestrem in France that

produces a multitude of products including polyols, native and modified starches,

proteins and derivatives, cyclodextrins, organic acids and resins (see Figure 1.6).

Cereal grains

(

single feedstock

)

Multi-products

Polyols

Native and

modified starches

Physical separation

Pre-treatment

Proteins and

derivatives

Dietary fibres

Chemical and/or

biochemical catalysis

Enzymatic process

Cereal sugars

Cyclodextrins

Fermentation

Organic acids

Multi-processes

Plant-based resins

Figure 1.6

Roquette site in Lestrem, France: an example of a phase II biorefinery.