Environmental Engineering Reference

In-Depth Information

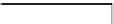

Enzyme

production

Microbial fermentation

Hexose

sugars

Hydrolytic enzymes

Milling & size

reduction

Lignicellulosic

biomass

(wood, agricultural

and forestry waste)

Pretreated

biomass

Enzymatic hydrolysis

Ethanol

Pretreatment

Pentose

sugars

Removal of

lignin

Microbial fermentation

Figure 7.7

Ethanol production from lignocellulosic biomass.

sugars; and (2) fermentation of the released sugars by yeast or bacteria. Ethanol

can be produced from lignocellulosic material by chemical and microbiological

hydrolysis processes. There are two main types of chemical hydrolysis process,

one that uses high acid concentrations (the concentrated hydrochloride acid pro-

cess, or CHAP) and another that was developed through a collaborative endeavor

between Canada, America, and Sweden (the CASH process) and uses dilute acid.

In the microbiological process, cellulose is broken down to sugar units by cellu-

lase enzymes. One big challenge in this ethanol production process is to avoid

degradation of sugar into other organic compounds such as furfural or 2-methy-

hydroxyfurfural in order to maintain high ethanol yields [59]. These compounds

act as inhibitors in the fermentation step.

A unique pilot plant for ethanol production from lignocellulosic feedstocks was

established at Ö-vik, Sweden in May 2004. The aim of the pilot plant was to develop

efficient continuous technologies for the various process steps in ethanol produc-

tion from forestry raw materials and other lignocellulosic feedstocks. Different raw

materials require different conditions during the production process, which also

needs to be optimized for every raw material. It was also considered important to

demonstrate that large-scale lignocellulosic ethanol production was possible and to

show that the production costs for cellulose-based ethanol could be decreased. The

plant is fitted with several pieces of equipment that make it possible to perform two-

step dilute acid and/or enzymatic hydrolysis on site. In 2005, ethanol from wood

chips (softwood, i.e. spruce) was produced in the plant for the first time. The plant

can process up to 2 tons of biomass per day, producing about 400 L of ethanol.

The lignin by-product is used for other purposes rather than just heat produc-

tion and power generation, and there is ongoing research into its potential applica-

tion as a precursor for the synthesis of other more valuable chemicals. In addition,

the lignin can be pelletized together with other biomass. For example, at the

Biofuel Technology Centre in Umeå, Sweden, lignin has been mixed with other

feedstocks to produce pellets that enable its efficient transportation and use as a

solid biofuel. The cost of ethanol production will decrease dramatically if meth-

ods that enable the conversion of lignin into valuable products can be developed.