Environmental Engineering Reference

In-Depth Information

There are several factors that influence the choice of conversion process including

the desired form of bioenergy, the type of and quantity of the available biomass

feedstocks, and environmental and economical constraints. Biomass materials

such as agricultural and forestry residues are often difficult to use directly in ther-

mochemical conversion processes for the production of certain energy products

due to their heterogeneous and bulky nature. They therefore need to undergo some

kind of pretreatment or physical upgrading process prior to use, as discussed in

Section 7.2. Biomass may also has a high water content, which must often be

reduced prior to thermochemical treatment. For all these reasons, biomass is often

crushed, dried, and milled before thermochemical processing. As discussed in

Section 7.2.6, torrefaction is another pretreatment process that can be used to

improve the thermochemical conversion of biomass by increasing gasification

efficiency and reducing smoke production during gasification.

7.4.1

Thermal Processing Equipment

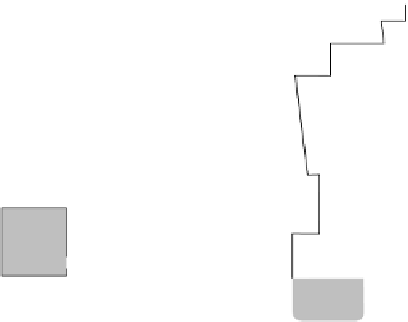

There are four main types of thermal processing equipment that are widely used

for biomass gasification, including: fixed bed gasifiers (and moving bed systems);

fluidized bed reactors (gasifiers); circulating fluidized bed (CFB) reactors; and

entrained flow systems, as highlighted in Figure 7.4. Passing gas over the biomass

at a high velocity in thermal processing systems generally promotes mixing and

enhances combustion efficiency.

(b)

Product

gas

(c)

Biomass

Gas

Oxygen

(a)

Cyclone

Cyclone

Cyclone

Freeboard

Product

gas

Ash

Bubbles

Ash

Cooling

screen

Fluid

bed

Biomass

Biomass

& sand

Heat

Sand

Air

Quench

water

Syngas

Slag

Biomass

feed

Air

Figure 7.4

Different kinds of reactors: (a) fluid bed reactor; (b) CFB; and (c) entrained flow

reactor. Reproduced with permission from Rashmi Kataria, Department of Forest Biomaterials

and Technology at SLU.