Environmental Engineering Reference

In-Depth Information

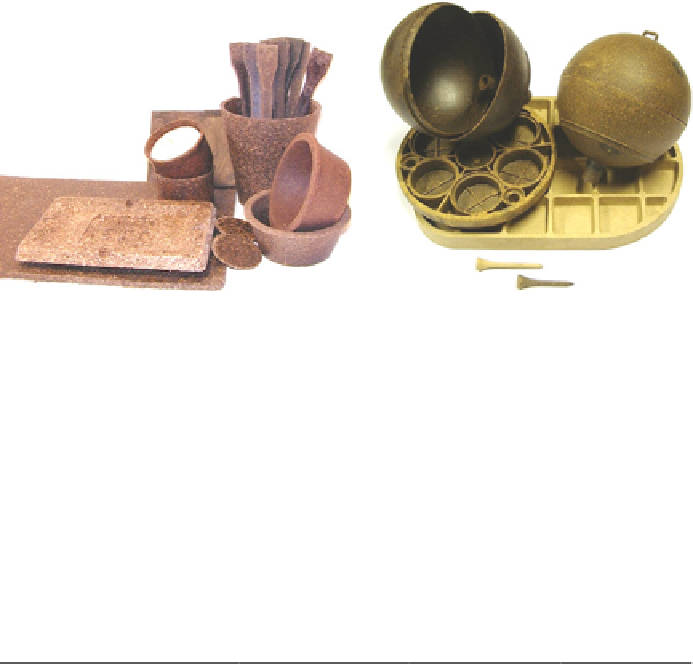

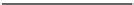

Figure 6.23

Examples of thermoplastic agromaterials obtained from sunflower oilcake and

whole corn plant.

Table 6.5

Average composition (%, dry matter basis) of the three most common feedstocks

used for the production of agromaterials.

Sunflower oilcake

Sugar beet pulp

Whole corn plant

Lipids

1

0

3

Sugars

6

0

7

Ash

7

5

5

Cellulose

12

23

21

Hemicelluloses and pectins

17

48

24

Lignin and phenolics

13

2

3

Starch

1

0

30

Protein

34

7

7

biopolymers can be plasticised

in situ

to constitute a natural continuous matrix for

cellulosic fibres.

Destructuring the native organisation of the raw agricultural products is possi-

ble with the combination of thermal, mechanical and chemical effects in an

extruder (Figure 6.24). In the first constraint zone, the matter is roughly crushed.

In the second zone, a compression (up to 20 bars) in the reverse screw induces a

non-degrading break of the structure when the moisture content and the tempera-

ture are 20-30% and 110-130°C, respectively. Water plays the roles of plasticiser

and lubricant, avoiding degradation under high shear. The same phenomenon

occurs with a higher compression and a lower shear in the die to complete the

transformation.

Starch plasticisation is obtained by gelatinisation of the grains in low-moisture

conditions leading to the 'melting' of the starch grains, the key phenomenon in the

transformation of the whole corn plant. The plasticised starch forms a continuous

matrix in which the defibrated fibres are embedded, as showed in Figure 6.25.