Image Processing Reference

In-Depth Information

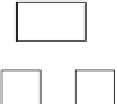

Protocol hierarchy

Network types

Company level

GAN

TOP

Factory level

WAN

MAP

Shop floor level

LAN

Cell

controller

Mini-MAP

Cell level

FAN

Process level

PLC

CNC

Fieldbus

Sensor-actuator

networks

Field level

(sensor level)

Sensors-actuators

FIGURE .

Hierarchical network levels in automation and protocols originally devised for them. (From Sauter, T.,

in

he Industrial Communication Handbook

, CRC Press, Boca Raton, FL, , .-.. With permission.)

with the availability of the Internet. In fact, Internet technology is penetrating all levels of this pyramid

allthewaydowntotheprocesslevel.

From GANs to LANs, the classification according to the spatial extension is evident. One step

below, on the field level, this criterion fails, because fieldbus systems or field area networks (FANs)

can cover even larger distances than LANs. Yet, as LANs and FANs evolved nearly in parallel,

some clear distinction between the two network types seemed necessary. As length is inappropri-

ate, the classical borderline drawn between LANs and FANs relies mostly on the characteristics of

the data transported over these networks. LANs have high data rates and carry large amounts of data

in large packets. Timeliness is not a primary concern, and real-time behavior is not required. Field-

bussystems,bycontrast,havelowdatarates.Astheytransportmainlyprocessdata,thesizeofthe

data packets is small, and real-time capabilities are important.

For some time, these distinction criteria between LANs and FANs were sufficient and fairly

described the actual situation. Recently, however, drawing the line according to data rates and packet

sizesisnolongerapplicable.Infact,theboundariesbetweenLANsandieldbussystemshavefaded.

Today, there are fieldbus systems with data rates well above Mbit/s, which is still standard in older

LAN installations. In addition, more and more applications require the transmission of video or voice

data, which results in large data packets.

On the other hand, Ethernet as the LAN technology is becoming more and more popular in

automation and is bound to replace some of today's widely used mid-level fieldbus systems. The

real-time extensions being under development tackle its most important drawback and will ulti-

mately permit the use of Ethernet also in low-level control applications. At least for the next years,

however, it seems that industrial Ethernet will not make the lower-level fieldbusses fully obsolete.

They are much better optimized for their specific automation tasks than the general-purpose net-

workEthernet.ButthegrowinguseofEthernetresultsinareductionofthelevelsintheautomation

hierarchy. Hence, the pyramid gradually turns into a flat structure with at most three, maybe even

only two levels.

Consequently, a more appropriate distinction between LANs and FANs should be based on the

functionality and the application area of these networks. According to this pragmatic argumentation,

a fieldbus is simply a network used in automation, irrespective of topology, data rates, protocols, or

real-time requirements. Consequently, it need not be confined to the classical field level, it can be

found on higher levels (provided they still exist) as well. A LAN, on the other hand, belongs to the

office area. his definition is loose, but mirrors the actual situation. Only one thing seems strange at