Environmental Engineering Reference

In-Depth Information

·

ε

R

=

λε

·

ε

=

ε

s

t

R

t

MGD

t

R

Time,

t

3.23

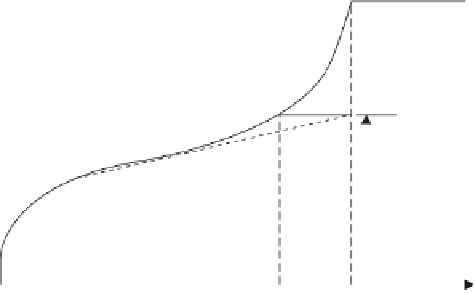

Representation of creep strain growth following the

Kachanov-Rabotnov model.

.

Phaniraj

et al

.

98

have established a correlation between the ratio of time to

Monkman-Grant ductility (

t

MGD

) and time to rupture (

t

R

) and the damage

tolerance parameter as given by

the creep curve would assume different shapes for different values of

λ

λ

.

⎡

⎢

⎤

⎥

⎤

⎦

λ

1

t

MG

D

−

1

[3.60 ]

⎡

⎣

=−

λ

t

R

t

Figure 3.24 is based on this Equation [3.60] and shows that

t

MGD

/

t

R

is essen-

tially constant for

> 4. The

t

MGD

was suggested as time for onset of true

tertiary creep damage and was considered to be an important parameter in

identifying the useful creep life of a material. It also describes the time for

which minimum creep ductility is ensured. Hence Phaniraj

et al.

contend

that the stress to cause

t

MGD

in 10

5

h can be used as a useful design criterion

for creep of elevated temperature components.

Before concluding we present a few examples where the concepts dis-

cussed in the previous sections may not be directly applied. Rather subtle

modifi cations to the models are necessary in order to simulate the actual

behavior of the material.

λ

3.7

Case studies illustrating the role of other factors

In the following section, the effects of impurities, second phases and multi-

axial loadings on creep of materials are discussed with examples taken from

various classes of materials including ionic solids.

Search WWH ::

Custom Search