Environmental Engineering Reference

In-Depth Information

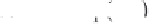

10

-2

T

= 838K

10

-3

Power-law breakdown

10

-4

n

~ 12

10

-5

10

-6

10

-7

n

~ 4

10

-8

n

~ 1

10

-9

10

-10

10

-11

10

-12

30

60

100

σ

(MPa)

200

300

3.22

Experimental creep rates obtained in 0.5Cr-0.5Mo-0.25V steel

838 K. The solid line corresponds to the predictions of the

-

projection

concept and the plot shows the sound agreement between the

experimental and theoretical predictions.

92

θ

),

(

(

)

)

(

()

4

[3.53 ]

εθ

1

1

θ

−

θ

−

θ

θ

θ

1

θ

4

θ

−

−

2

θ

2

)

)

θ

θ

3

3

3

4

4

where

θ

1

scales the primary creep regime,

θ

2

is a rate parameter govern-

ing the curvature of the primary stage,

θ

3

scales the tertiary creep regime

and

4

is a rate parameter quantifying the shape of the tertiary curve. These

parameters are found to change with stress and temperature conditions and

accordingly infl uence a change in the shape of the creep curve. A determina-

tion of the stress and temperature dependencies of the

θ

parameters would

allow the prediction of long term creep properties. Furthermore Wilshire

counters the widely accepted view of transitions in creep mechanisms with

changing stress and temperature conditions. The creep characteristics of a

0.5Cr-0.5Mo-0.25V ferritic steel could thus be described by the

θ

-projection

over a wide range of stress values based on a single dislocation-based mech-

anism. However, as shown in Fig. 3.22, there are defi nite changes in stress

exponent values with changing stress. Wilshire argues that if different mech-

anisms operate in different stress and temperature regimes, data collected

in one mechanism regime should not be able to predict the creep behav-

ior in a different mechanism regime. Furthermore Wilshire contends that

the

θ

θ

-

projection approach can be utilized to quantify material behavior in

Search WWH ::

Custom Search