Environmental Engineering Reference

In-Depth Information

-

Q

1

/

R

-

Q

1

/

R

-

Q

2

/

R

-

Q

2

/

R

1/

T

(arb. units)

1/

T

(arb. units)

3.15

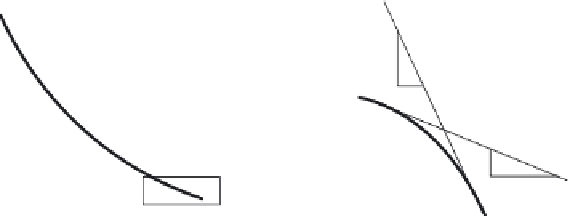

Arrhenius plots for (a) parallel mechanisms and (b) sequential

mechanisms of creep.

⎛

⎜

⎞

⎟

⎛

⎜

⎞

Q

RT

Q

RT

−

1

1

exp

1

1

exp

2

[3.41 ]

−

()

−

⎛

⎝

⎛

⎝

ε

ε

⎠

+

ε

01

02

.

The Arrhenius plot for such a scenario is illustrated in Fig. 3.15b. Here, in

any given temperature range, the

s

lower

process dominates the creep rate.

However the amount of creep strain may not necessarily be controlled by

the slower process. It could be possible that the slower mechanism contrib-

utes little strain but allows the other mechanism with a greater strain contri-

bution to operate. The dislocation glide-climb creep mechanism described

earlier (Fig. 3.12) and Equations [3.30-3.34] is an example for this type of

series mechanism while the simultaneous occurrence of N-H and Coble

creep (Equations [3.17] and [3.18]) falls under parallel mechanisms.

3.5

Transitions in creep mechanisms

A material experiences transitions in mechanisms when the applied stress

or the test temperature is varied.

3.5.1 The Bird-Mukherjee-Dorn equation

4

As discussed earlier, for the same temperature and stress combinations, a

material can creep via different mechanisms if the grain size is different. In

fact, as Equation [3.25] would suggest, a material creeps with higher strain

rates for smaller grain sizes. For relatively smaller grain sizes, creep could

occur by diffusion of vacancies through the grain boundaries. But larger

grain sized materials, under the same stress and temperature conditions,

could creep by dislocation-based processes or by lattice diffusion processes.

Search WWH ::

Custom Search