Environmental Engineering Reference

In-Depth Information

100

40

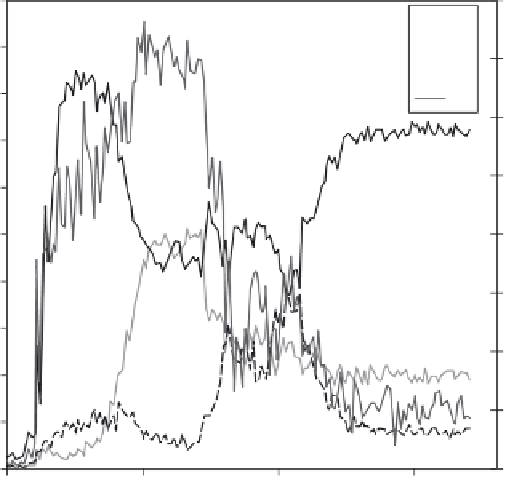

Fe

Cr

Ni

O

90

35

80

30

70

25

60

50

20

40

15

30

10

20

5

10

0

0

0

50

100

Position (nm)

150

2.1

EDX profi le on 304 L exposed to water (360°C, pH

325°C

= 7.2).

Finally, passivation is the process of building a protective layer of oxide isolating

the surface of the material from the aggressive environment. Some corrosion

inhibitors help the formation of such layers. Figure 2.1 shows energy-dispersive

x-ray (EDX) analysis of the oxide formed on stainless steel exposed to water

at 360°C (−600 mV

SHE

, pH

325

°

C

= 7.2). The passive fi lm is the 50 nm-thick layer

containing a signifi cant level of chromium at the surface of the metal.

2.2

Pressurized water reactors and the main

types of corrosion

2.2.1 PWRs

A large variety of structural metals present in primary and secondary

circuits of PWRs suffer corrosion:

Carbon steels

are cheap iron-base metals with less than 1% of alloying

element present. These materials exhibit a poor resistance to corrosion

but their forming, machining and welding are superior.

Low-alloy steels

are iron-base metals containing a few percent of, for

example, nickel, chromium, molybdenum, vanadium, which are usually

Search WWH ::

Custom Search