Environmental Engineering Reference

In-Depth Information

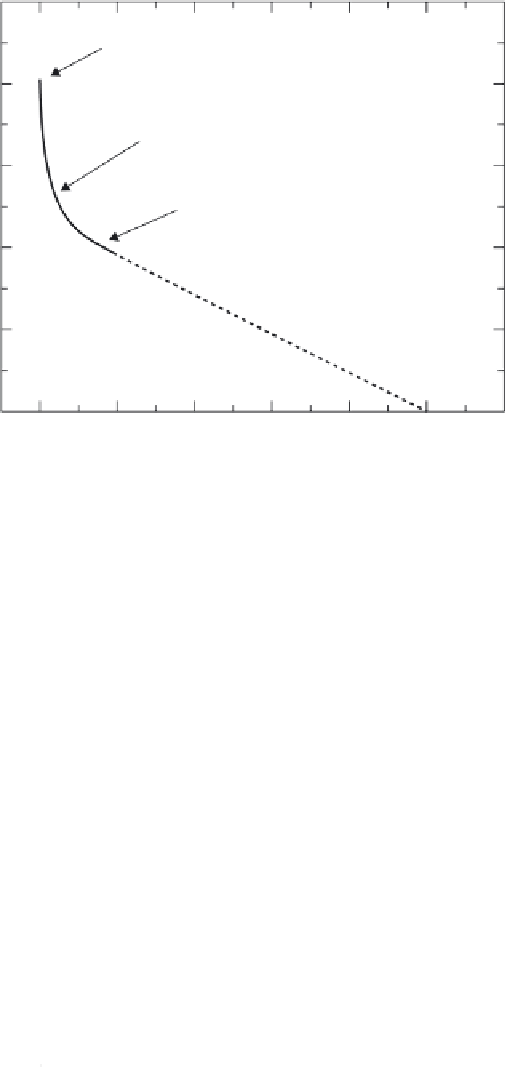

0.020

Vacuum annealed

0.016

3.910

16

n/cm

2

0.012

10

17

n/cm

2

2.8

0.008

0.004

210

18

n/cm

2

0.000

0

4

8 12

10

-17

φ

t

(n/cm

2

)

16

20

24

1. 17

Effect of neutron irradiation on concentration of nitrogen

in solution in mild steel.

25

material, whereas increased strength and ductility are noted following irra-

diation to around 2

×

10

18

n/cm

2

; but, after irradiating at the highest fl uence

level of 1.4

10

19

n/cm

2

the ductility decreased to around 2% with possi-

ble fracture during Luders band propagation. These results are in contrast

to those at room temperature where no DSA or blue brittleness is noted

(Fig. 1.14b). At 100°C in mild steel where jerky fl ow started, the ductility

decreased to 11% while it increased to ~20% following neutron irradia-

tion to 10

18

n/cm

2

. The fact that strength increased along with an increase

in ductility implies that toughness (as defi ned by the area under the stress-

strain curve) increases at temperatures where DSA is suppressed following

radiation exposure. This is clearly shown in Fig. 1.20 which compares the

toughness (

J

) for mild steel before and after neutron irradiation to 2

×

10

18

n/cm

2

.

28

Normal radiation embrittlement is noted at ambient temperature

while an increase in toughness is observed at elevated temperatures follow-

ing radiation exposure. The measured toughness is sensitive to the strain-

rate of testing and a minimum toughness value is obtained when tested

over a strain-rate range. This minimum in the unirradiated material occurs

at higher temperatures for increased strain-rates and follows an Arrhenius

relation (

×

QR

/

/

T

T

where

T

c

is the temperature at which minimum tough-

ness occurs) with the activation energy (

Q

) identifi able with that for diffu-

sion of C and N in steel. Thus these synergistic effects of neutron irradiation

ε

=

Ae

−

Search WWH ::

Custom Search