Environmental Engineering Reference

In-Depth Information

Reentrant

corners

Former

Baffle

former

bolts

Baffle

Core barrel

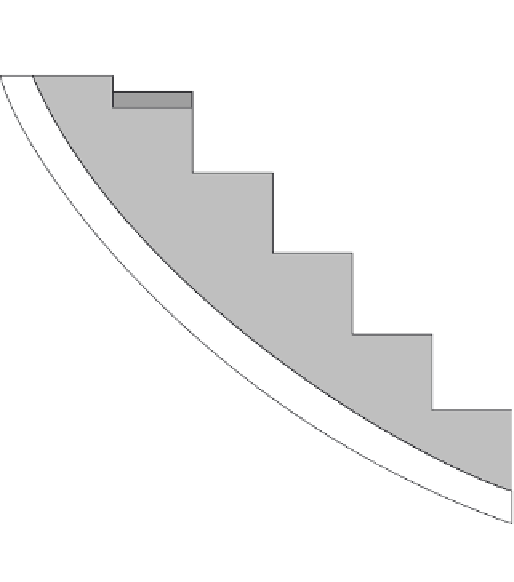

9.5

PWR baffl e bolts (NUREG/CR-6897/ANL-04/28, Assessment of Void

Swelling in Austenitic Stainless Steel Core Internals, H. M. Chung).

Recently, concerns have increased for the integrity of the primary ves-

sels and baffl e bolts for PWRs due to radiation hardening and loss of ten-

sile strength (these bolts hold the fl ow baffl es together on the outside of

the core, see Fig. 9.5). Cracked welds around the penetration tubes through

PWR reactor vessel heads have allowed internal corrosion of the alloy steel

below the weld overlay material resulting in a potential small break LOCA

situation (NRC, 2008a). In BWRs, breaking of welds due to excessive vibra-

tion from the large steam fl ow as well as boiling within the core and crack-

ing of the coolant piping continue to be an issue.

A key integrity issue for PWRs is the reactor coolant pump seal. This is a

component that must have a minimal fl ow since it is a leak path for primary

coolant from the primary coolant system. This has been a long-standing

issue that comes and goes for various plants; for some plants is the highest

potential issue for a small break LOCA.

Over the past 40 years of LWR operations, these issues have led to a new

emphasis on the importance of effective chemistry control; research into

new additives such as zinc for nuclear service; the need for better design

methods for components specifi cally to take into account vibration issues

in both the core area and the primary side piping; and the introduction of

new alloys that can withstand the rigors of very clean water. Examples of

Search WWH ::

Custom Search