Environmental Engineering Reference

In-Depth Information

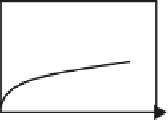

Fast flux

Core periphery

5.2

Schematics showing fuel outer channel bowing at core periphery

due to large fast neutron fl uence. Largest degree of bowing in

BWR

s

occurs at the core periphery due to the fl ux profi le. Also the type of

FA

bow seems to be very dependent on core location (Strasser

et al

.,

2010a).

5.2.2 Pellet-cladding interaction

Stresses which induce both PCI (usually denotes combined mechanical

and chemical pellet-cladding interaction) and PCMI (usually denotes pel-

let cladding mechanical interaction) are caused by expansion of the fuel

pellet against the cladding during power increases (Adamson

et al

., 2006/7;

Strasser

et al

., 2010a). PCI failures are driven by a stress corrosion crack-

ing (SCC) assisted component resulting from fi ssion product release from

the fuel, while PCMI failures are generally due to purely mechanical crack-

ing, often enhanced by a reduction in cladding ductility due to formation of

local hydrides at the clad outer surface. At the micro level, the PCI crack

always starts at the cladding inner surface and propagates towards the outer

cladding surface while the PCMI crack propagates from the outer to inner

surface.

PCI is associated with local power ramps during reactor start-up or power

manoeuvring (e.g. rod adjustments/swaps, load following) as shown sche-

matically in Fig. 5.3, and is caused by the combination of cladding stress due

to the power increase and the infl uence of iodine, caesium and cadmium

released during the power increase in a susceptible material (Adamson

et al

., 2006/ 2007 ; Strasser

et al

., 2010a). This combination of stress, embrittling

Search WWH ::

Custom Search