Environmental Engineering Reference

In-Depth Information

on several important variables include cold work, Sn content, alloy content

and fabrication history. The lowest temperature dependency is ascribed to

heavily cold-worked Zircaloy-2 and -4, while the highest is for Zr-2.5Nb

CANDU pressure tubes. (It should be noted that the operating temperature

of CANDU pressure tubes is generally below 310°C, 583K.)

Several metallurgical factors infl uence creep. Disturbances in the regular-

ity of the lattice such as those caused by under- or over-sized atoms interfere

with dislocation motion and act as sinks for irradiation-produced vacancies

and SIAs. Of particular importance are the elements disturbing the regular-

ity of the lattice and having appreciable solubility in Zr: Sn, Nb and O, all of

which increase the creep strength (Seibold & Garzarolli, 2002). On the other

hand, an element having low solubility,

S

, has been proposed to increase

the creep strength of Zr-1Nb alloys (Soniak

et al

., 2002; Mardon and Bordy,

2004 ; Rebeyrolle

et al

., 2004). The mechanism is not yet well defi ned, but is

proposed to be a dislocation interaction effect.

Cold working affects three metallurgical parameters: dislocation den-

sity, grain shape and texture (anisotropy), all of which can affect creep rate.

The general observation is that cold worked or cold worked/stress relieved

(CWSRA) zirconium alloys have higher creep rates than RXA alloys. An

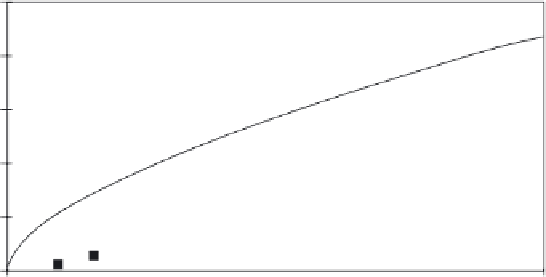

example is shown in Fig. 4.69 (Soniak,

et al

., 2002 ). Mechanistic analyses

are, once again, not fi rm on a quantitative effect of dislocation density, but

most, including varieties of the SIPA mechanism, predict higher in-reactor

creep rates with higher dislocation density,

ρ

. Stress relaxation experiments

M4

M5

Zy-4 SRA

Zy-4 RXA

0.025

350°C 90 MPa

0.020

0.015

0.010

0.005

0.000

0E+00

1E+25

2E+25

3E+25

4E+25

5E+25

6E+25

7E+25

8E+25

Fast fluence

φ

t

(n/m

2

)

4.69

Effect of metallurgical condition and alloy composition on

hoop creep strain vs fl uence for SRA and RXA Zircaloy-4 and RXA

M4 and M5. (Source: Reprinted, with permission, from Soniak

et al

.

(2002), copyright ASTM International, 100 Barr Harbor Drive, West

Conshohocken, PA 19428.)

Search WWH ::

Custom Search