Environmental Engineering Reference

In-Depth Information

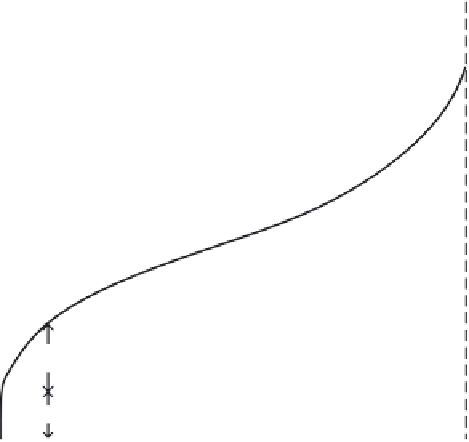

Tertiary

(unstable)

Rupture

Secondary

(steady-state)

~

constant

σ

Primary

(transient)

ε

sc

ε

c

ε

e

+

ε

p

0

t

, Time

4.68

Strain vs time behaviour during creep under constant load, and

the three stages of creep.

important parameters infl uencing creep strains and rates. A tertiary stage is

not reached except in very rare, localized high stress cases.

In-reactor creep of any component or specimen consists of three parts:

(1) thermal creep (which in most practical cases is small, and in all cases is

different from thermal creep of unirradiated material), (2) true irradiation

creep and (3) irradiation growth. The most common practice is to assume

that the three parts are independent and additive, although from a mecha-

nistic view this is questionable. In data analyses, only in-reactor creep has

been analysed typically, without any separation of thermal and irradiation

creep components; if possible, any irradiation growth should be subtracted

from the experimental creep me

a

surements.

The steady state creep rate,

, is most often expressed as a function of

ε

variables:

Q

RT

d

d

t

ε

−

A

[4.2]

ε

(,

p

pn

σ

,)

f

φ

e

fG

ρ

==

σ

e

,

G

and in-reactor strain,

ε

, is often expressed for a specifi c alloy and alloy con-

dition as:

Q

RT

−

[4.3]

A

()

φ

mn

σ

ε

t

σ

e

Search WWH ::

Custom Search