Environmental Engineering Reference

In-Depth Information

10

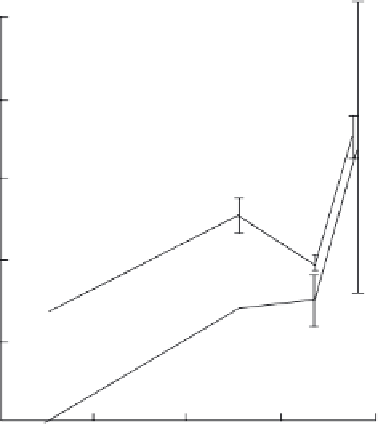

Annealed

Zircaloy-2

F

L

= 0.1

25% cold-worked

Zircaloy-2

8

6

4

2

300

400

500

600

700

Temperature (K)

4.66

Temperature dependence of growth in Zircaloy-2 at high fl uence

(Rogerson, 1988).

curve) steadily increases with increasing temperature. Also, as indicated

in Fig. 4.65, the fl uence at which growth breakaway occurs gets smaller

as temperature increases. Also note in Fig. 4.66 (Rogerson, 1988) that at

temperatures above about 360°C (633K) the growth rate is the same for

recrystallized (RXA) and cold worked (SRA or CWSRA) materials.

Temperature effect information is given by Gilbon & Simonot (1994)

and Gilbon

et al

. ( 2000 ) and confi rms that growth dramatically increases

between the temperatures 350°C and 400°C (623-673K). Gilbon

et al

. ( 2000 )

also give data showing that growth of the M5 alloy at 5 × 10

25

n/m

2

decreases

from 0.08% at 280°C (553K) to 0.04% at 350°C (623K).

The effect of temperature on growth rates of cold-worked Zr-2.5Nb is

given by Holt

et al

. (2000). In the range of interest for CANDU reactors,

that is 290-317°C (563-590K), the growth rate decreases with increasing

temperature at high or low fl uences. This is slightly different and opposite

to that observed for Zircaloy, but the range of temperature data available is

smaller than for Zircaloy.

The practical implications of the discussed temperature dependence

should be clear. For BWRs and CANDUs variations in growth should be

small and predictable, at least for the alloys currently used, and for PWRs

variation may be large and, particularly above about 350°C (623K), may be

unpredictable with our current state of knowledge.

Search WWH ::

Custom Search