Environmental Engineering Reference

In-Depth Information

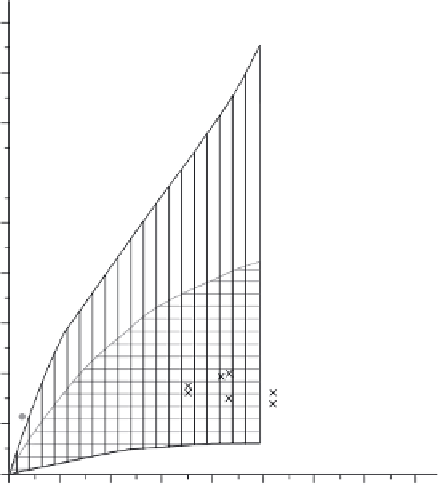

BWR shadow corrosion

360

Siemens

1

GNF2

Westinghouse Atom

3

LK2

LK2+, LK3

320

280

240

200

160

120

80

40

0

0

10

0 0 0 0 0 0 0

MWd/kgU

4.56

Shadow corrosion data of various BWR fuel vendors' claddings.

(Source: Figure modifi ed according to Hoffmann and Manzel (1999);

Potts (2000); Zwicky

et al

. (2000). Copyright 2000 by the American

Nuclear Society, La Grange Park, Illinois.)

this illustrates the trend for saturation of the oxide thickness with fl uence or

burnup. In most cases, shadows have not caused fuel performance problems.

The upper curve in Fig. 4.50, is an exception for a specifi c cladding condition,

called Enhanced Spacer Shadow Corrosion (Zwicky

et al

., 2000 ).

A number of experiments have been conducted to elucidate the details of

the shadow corrosion mechanism. Combined with the commercial reactor

observations, these experiments reveal:

1 A variety of metals are observed to cause shadows on Zircaloy. These are:

(a)

Stainless steel (many)

(b)

Pt (Shimada

et al

., 2002; Johnson

et al

., 1974 )

(c)

Hf (Shimada

et al

., 2002)

(d)

Inconel X750, X718 (many)

(e)

Inconel 600 (Adamson

et al

., 2000 )

(f)

Welded regions on Zircaloy (Chen & Adamson, 1994 ; Shimada

et al

.,

2002).

Search WWH ::

Custom Search