Environmental Engineering Reference

In-Depth Information

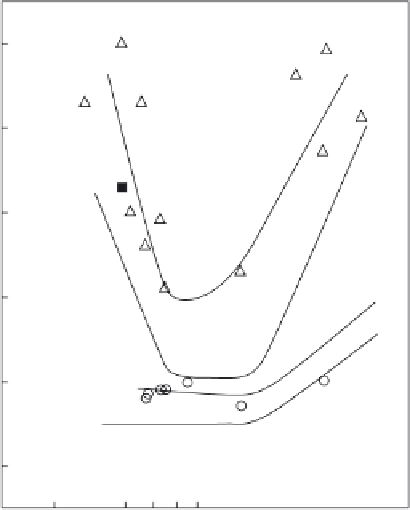

60

4 cycles

50

40

3 cycles

30

20

2 cycles

1 cycle

10

Each point is the average

from several fuel rods

0.03

0.05

0.1

0.2

0.3

Average precipitate size (m)

4.47

Effect of SPP size on corrosion of Zircaloy-2 cladding. (Source:

Reprinted, with permission, from Garzarolli

et al

. (1994), copyright

ASTM International, 100 Barr Harbor Drive, West Conshohocken, PA

19428.)

Zircaloy-4, which does not contain alloying quantities of Ni, is also

susceptible to increased corrosion when SPPs dissolve. An example is given

in Fig. 4.42 for Zircaloy-4 with a relatively large SPP, about 0.2 µm average

size determined by TEM (Garzarolli,

et al

., 2002). It is seen that when the

volume fraction of SPPs gets very low, corrosion increases dramatically.

A compilation of data for Zircaloy-2 and -4 given by Garzarolli in

Adamson

et al

. (2006) and Garzarolli

et al

. (2011b) illustrates that Zircaloy-4

generally has higher corrosion than Zircaloy-2 (see Fig. 4.49). However, the

hydrogen pickup fraction (HPUF) for Zircaloy-4 appears to stay remark-

ably low at high burnup, as indicated by the data of Miyashita

et al

. ( 2006 )

and the correlation given in Fig. 4.50 .

In PWRs nodular corrosion in unlikely to occur due to high hydrogen

and low oxygen in the water. Accelerated uniform corrosion does occur for

Zircaloy-4 in PWRs as seen in Fig. 4.51 (and Fig. 4.48) and the HPUF is rel-

atively low, as in BWRs (Fig. 4.52).Those fi gures also show that M5 (which is

basically a Zr1Nb alloy with 300-500 ppm Fe) does not undergo accelerated

Search WWH ::

Custom Search