Environmental Engineering Reference

In-Depth Information

4.39

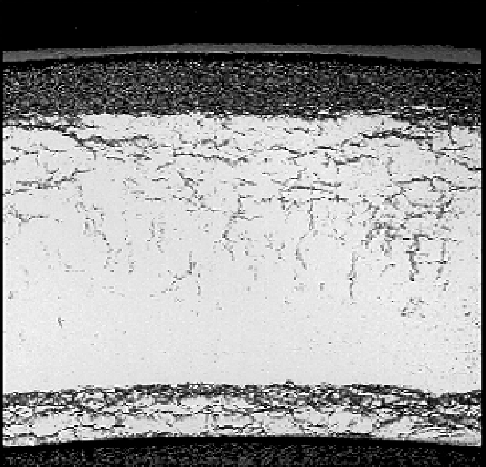

Dense hydride rim on the outer side, BWR liner fuel rods with

low Fe and Si Zry-2 cladding exposed at corner position to high heat

fl uxes to 53.5 MWd/kgU with an average hydrogen content of 1600

ppm (Miyashita

et al

., 2007). Copyright 2007 by the American Nuclear

Society, La Grange Park, Illinois.

Hydride distribution in fuel rods having very high heat fl ux can be quite

complicated, as illustrated for an extreme case in Fig. 4.39 for a Zircaloy-2

BWR cladding with a liner of zirconium. A dense hydride rim is seen at the

outer surface (a condition more common in PWR rods than BWR ones), mixed

radial and circumferential in the outer interior, a zone denuded of hydrides on

the inner interior and substantial hydriding of the inner zirconium liner. High

burnup performance of both BWR and PWR rods may be affected by such

hydride distribution. One evaluation is given by Garzarolli

et al

. ( 2010 ).

4.5

Corrosion of zirconium alloys

We proceed here with descriptions of corrosion phenomena, which often limit

the lifetime of core components.

4.5.1 Types of corrosion and comparison between

PWRs and BWRs

Corrosion of zirconium alloys used in the core of nuclear power plants (and

the accompanying absorption of hydrogen in the zirconium metal matrix)

Search WWH ::

Custom Search