Environmental Engineering Reference

In-Depth Information

texture;

time.

The radial hydrides visible in metallographic cross sections can be present

in a wide variety of sizes and distributions as well as fractions of the total

hydrides present.

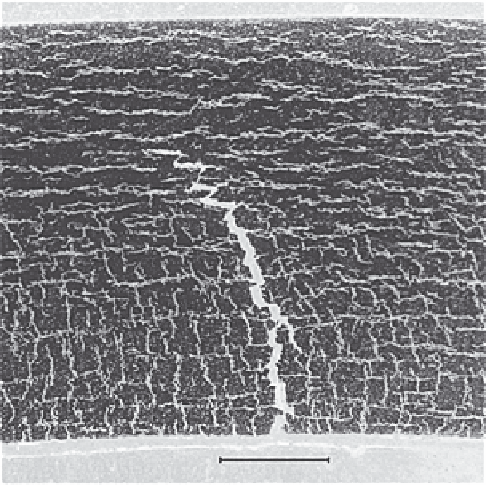

Radial hydrides in zirconium alloy cladding are undesirable because

they reduce the critical stress intensity required to propagate a radial crack

through the wall of the cladding during handling or transportation, as shown

by mechanical property data in the previous section. This is illustrated in

Fig. 4.38, where it is seen that cracks propagate along radial hydrides, but are

blunted in the circumferential hydride region. For this reason considerable

attention and effort is expended to defi ne the conditions for radial hydride

formation and evaluate their effect on mechanical properties and the per-

formance of the fuel, particularly during hypothetical accidents. One of the

objectives of the dry storage regulations in the United States is to limit the

conditions that could result in hydride reorientation and affect fuel recon-

fi guration during handling and transport.

Since one of the preferred hydride sites is the grain boundary, RXA

material with equi-axed grains is more susceptible to radial hydride forma-

tion compared to SRA material with grains elongated in the axial direction.

This is illustrated in Fig. 4.40 for SRA Zircaloy-4 and RXA Zircaloy-2.

4.38

Cracks propagating due to a hoop stress (along horizontal

direction in fi gure) (Daum

et al

., 2005).

200

μ

m

Search WWH ::

Custom Search