Environmental Engineering Reference

In-Depth Information

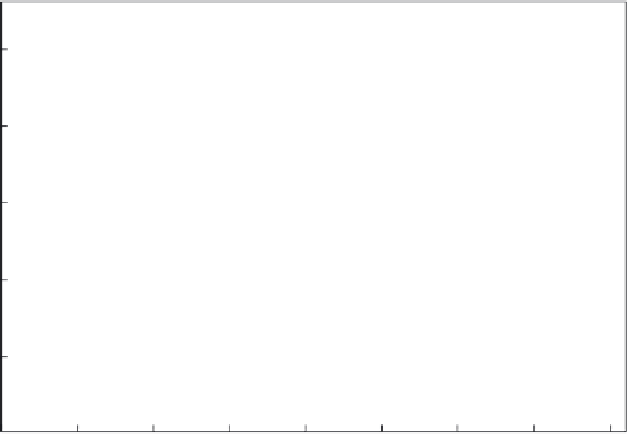

Test load - 100 grams

Zipcaloy-2 (288°C)

250

326 °C

Zipcaloy-2

200

343°C

Low-oxygen sponge Zirconium

150

Crystal bar

Zirconium

100

343 °C

Irradiation

Temperature (°C)

326°C

~ 288 371-374

50

Zircaloy-2

Low-oxygen sponge Zr

Crystal bar Zr

0

0

1

2

3 4

Neutron fluence,

E

> 1 MeV (10

21

n/cm

2

)

5

6

7

8

4.26

Knoop microhardness vs fast neutron fl uence for zirconium and

Zircaloy-2 (Tucker & Adamson, 1984).

characteristics anneal out at temperatures above about 400°C, although the

rate of annealing is more sluggish for Nb-containing alloys.

4.4.3 Effects of hydrides on ductility

A brief summary of hydride effects is given here to provide background for

pellet-cladding mechanical interaction (PCMI) type failures. All zirconium

alloy reactor components absorb hydrogen during reactor service through the

corrosion reaction between zirconium and water. Basics of these phenomena

are given in ZIRAT Special Topical Reports (Cox & Rudling, 2000; Adamson

et al

., 2006 ; Strasser

et al

., 2008). Hydrides tend to embrittle zirconium alloys

and therefore their effects are important for in-reactor normal service, for

ex-reactor handling operations and for accident and transient scenarios such

as LOCA and RIA. It is thought that individual hydrides themselves are actu-

ally brittle at all normal reactor temperatures (Simpson & Cann, 1979; Shi &

Puls, 1999); and it is clear that high concentrations of hydrides (5000-16 000

ppm) are very brittle, as in hydride blisters or rims.

Under normal conditions, hydride platelets form in the circumferential

direction in fuel cladding illustrated in Fig. 4.27a, but under some circum-

stances such as during long term storage or during power transients they

Search WWH ::

Custom Search