Environmental Engineering Reference

In-Depth Information

1.0

0.9

Irradiated Zircaloy

2.2

10

21

n/cm

2

523K

×

0.8

0.7

0.6

0

5

10

15

20

25

Distance along gauge length, mm

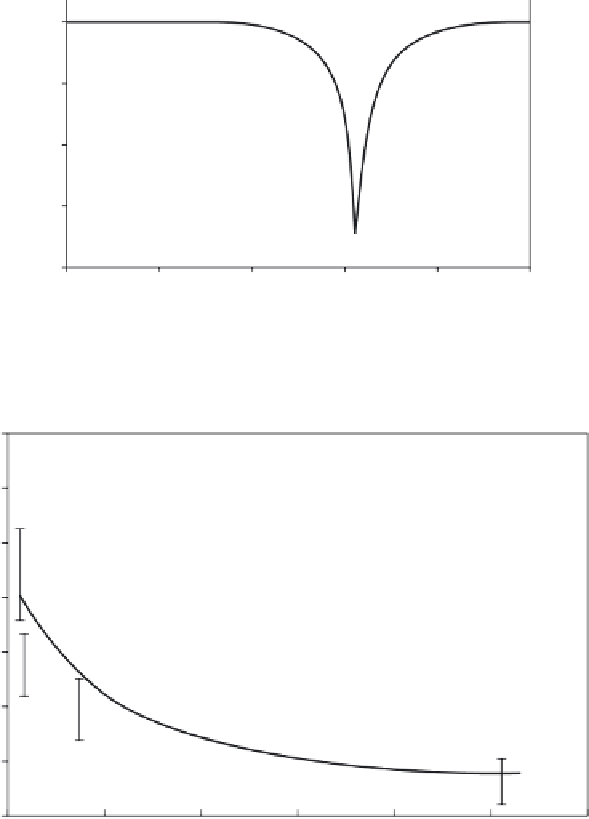

4.23

Deformation expressed as ratio of cross sectional area to original

area measured along the specimen gauge length (Williams

et al

., 1974).

7

Irradiated zircaloy

Strain rate: 3.33-83.3

×

10

−

5

s

−

1

Fluence: 1.3-11

6

10

21

n/cm

2

Test temp: 561-623K

×

5

4

3

2

Best estimate

1

0

0

5

10 15

Nominal gauge length, mm

20

25

30

4.24

Effect of specimen gauge length on uniform elongation.

(Source: Reprinted, with permission, from Adamson

et al

. (1986),

copyright ASTM International, 100 Barr Harbor Drive, West

Conshohocken, PA 19428.)

basically the same material. These data show that strain values developed

for use as failure criteria or strain limits are not real material properties, but

are strongly infl uenced by the specimen design used to obtain the data.

For burst tests of irradiated materials at 350°C (623K) (Onimus

et al

.,

2004) careful laser imaging measurements indicate that tubing deformed

Search WWH ::

Custom Search