Environmental Engineering Reference

In-Depth Information

gain basic understanding about the material behavior. It has been recog-

nized that hoop strain in a clad tube is a vital parameter in the breach of fuel

clad, and evaluation of their creep and burst behaviors is very important to

assess the integrity of the tube.

117

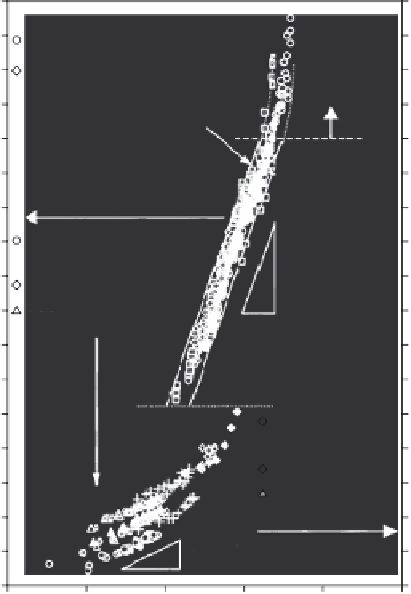

Steady-state creep-rates at relatively high

(>5 × 10

−4

E

) followed the same behavior as described earlier exhibiting

power-law creep behavior with exponential dependence at higher stresses

and were identifi ed as due to dislocation glide-climb creep mechanisms. At

low stresses, viscous creep with the characteristic

n

= 1 was indeed reported

as expected. Figure 3.29 summarizes the various sets of results in terms of

Dorn parameters for Zr-alloys.

118

Bernstein

119

observed that both Zircaloy-2

and pure Zr exhibit a stress exponent value of unity at low stresses which

increases to 4.6 and 6, respectively, at higher stresses. The data produced by

MacEwen

et al

.

120

also showed that the

n

increases with stress (for compa-

rable

-Zr with

comparable purity and in the comparable low stress range, but at slightly

higher temperature, showed a stress exponent value of 7.5 and the

n

value

reduced at higher stresses indicating operation of series mechanisms (see

σ

/

E

). On the contrary, data from Ardell and Sherby

121

for

α

Zirconium

10

-1

10

-7

Pahutova

et al.,

99.8%, 400-750°C

Bernstein 99.95%, 567°C

Power-law

breakdown

10

-3

10

-9

Ardell

et al.,

99.8%, 660-810°C

Gilbert

et al.,

99.8%,50-850°C

Warda

et al.,

99.95%, 450-550°C

10

-5

10

-11

MacEwen

et al.,

99.95%, 597-702°C

10

-7

10

-13

Novotny

et al.,

99.8%, 470-750°C

Prasad

et al.,

99.8%, 540-604°C

Bernstein 99.95%, 520-620°C

Fala

et al.,

99.8%, 475-700°C

n

~ 6.4

10

-9

10

-15

10

-11

10

-17

1.58-243

μ

m

10

-13

10

-19

1.6-55

μ

m

4.5-62

m

4.8-87

μ

m

μ

10

-15

10

-21

n

~ 1.1

10

-17

10

-23

10

-6

10

-5

10

-4

10

-3

10

-2

10

-1

σ

/

G

Search WWH ::

Custom Search