Agriculture Reference

In-Depth Information

Table 23. Experimental conditions for Coal-Vinasse test

Coal flow (kg/h)

2.1

Coal flow (kW)

17.5

Vinasse flow (l/h)

1.65

Vinasse flow (kg/h), Density = 1320 kg/m

3

2.2

Coal to Vinasse feed ratio (kg/h)/(kg/h)

0.95

Coal (%)

48.8

Vinasse (%)

51.2

Coal only feed time (hrs)

1.27

(Coal + Vinasse) feed time (hrs)

0.61

Total coal feed time (hrs)

1.88

Total coal feed (kg)

3.95

Total vinasse feed (kg)

1.34

Coal to vinasse mass ratio (kg/kg)*

2.95

Sand to vinasse ratio (kg/kg)*

5.6

*Based on the total fuel mass input into the bed

1000

440

400

900

360

800

320

700

280

600

240

500

200

400

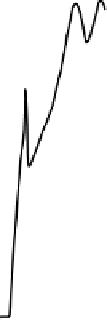

Bed Temperature (C)

Freeboard Temperature (C)

Bed Pressure (mmWg)

160

300

120

200

80

100

40

0

0

0.00

0.40

0.80

1.20

1.60

2.00

2.40

2.80

Time (hrs)

Figure 14. Temperature and Pressure observations during coal vinasse agglomeration test.

There were found some hard sintered bed agglomerates as shown in figure 15b. During

the tests the sampling probe of the flue gas analyser was also seen to be deposited with white

material, most likely NaCl and KCl, see Figure16a. There were also white deposits found on

the feed pipe, see Figure 16b, which may be composed of alkaline compounds.

Results of SEM analysis are given in Table 24 and SEM scan is shown in Figure 17. Gas

analyses of the test are given in Table 25. It can be seen from the table that there is an

increase in SO

2

emissions when vinasse is introduced. This is because vinasse has significant

amounts of sulphur in it. However the increase in SO

2

does not reflect the high amounts of

5% sulphur in vinasse. Thus it was thought that the sulphur behaved differently in the